Every year, businesses lose millions of dollars to a problem that often goes overlooked: product damage during shipping. It remains one of the leading causes of returns, warranty claims, and disappointed customers—yet it's also one of the easiest issues to fix.

If you're seeing an increase in damage-related claims, it may be time to re-evaluate the one element designed to protect your product throughout transit: your packaging.

The best part? Solving the issue doesn't usually require a full packaging redesign. In many cases, a simple adjustment to the internal cushioning or protective materials is all it takes.

Why Packaging-Related Damage Is So Common

Even the strongest box or crate can't fully protect a product on its own. True protection comes from the internal packaging—and this is where many companies fall short. Far too often, businesses rely on:

●Generic foam blocks or sheet materials

●Loose-fill options such as peanuts or paper

●Molded pulp inserts or vacuum-formed trays

While these materials may seem adequate, they frequently fail in real-world shipping environments—especially for products that are heavy, fragile, uniquely shaped, or exposed to rough handling through parcel or freight carriers.

Typical issues include:

●Products shifting inside the packaging

●Impact damage from drops

●Vibration-related wear during transport

●Inadequate cushioning against pressure or crushing

When the packaging isn't engineered to match the product, damage becomes almost unavoidable.

What's the Best Material for Reducing Damage Claims?

Foam is one of the most reliable and adaptable packaging materials available. When selected and engineered correctly, it absorbs shock, minimizes vibration, withstands compression, and provides precise support exactly where your product needs it.

Why is foam such an effective choice?

Superior Energy Absorption

Foam behaves like a shock absorber, compressing on impact to minimize the force transferred to your product. Whether a package is bumped, dropped, or mishandled, foam helps cushion the blow.

Lightweight Strength

With an excellent strength-to-weight ratio, foam enhances protection without adding significant shipping weight or cost.

Customizable Performance

Available in a wide spectrum of densities and firmness levels, foam can be perfectly matched to the size, weight, shape, and fragility of nearly any item.

Moisture and Chemical Resistance

Closed-cell foams offer strong resistance to water, oils, and chemicals—ideal for industrial components or outdoor products that require clean, dry transit conditions.

Reusable and Sustainable Options

Materials like expanded polypropylene (EPP) support reusable or returnable packaging systems, reducing waste and long-term operational costs.

Why Custom-Converted Foam Delivers Superior Protection

Placing a generic foam block or sheet in a box may offer some cushioning, but it rarely provides the level of protection your product truly needs. Custom-converted foam, however, offers a significant advantage because it is:

Precisely Tailored to Your Product

Using advanced fabrication methods—such as die cutting, waterjet cutting, and CNC routing—we create inserts, cavities, and supports that match your product's exact dimensions. The result: no shifting, no guesswork, and no unnecessary material.

Engineered for Optimal Performance

We help you choose the ideal foam type, thickness, and density for your application. This ensures maximum protection without unnecessary complexity or cost.

Designed for Your Shipping Environment

Whether your product ships by air, parcel, freight, or in a returnable packaging system, your logistics conditions matter. We design foam solutions that account for handling methods, transit cycles, and environmental factors to ensure real-world durability.

A Lower Total Cost of Ownership

While custom foam may cost more upfront than off-the-shelf options, it significantly reduces damage-related expenses—including returns, replacements, warranty claims, and customer dissatisfaction—resulting in substantial long-term savings.

How to Choose the Right Foam for Your Packaging

There is no single"best"foam. The ideal material depends on your product's weight, fragility, handling conditions, and shipping environment.

Best for: Lightweight, fragile products

Pros: Soft, flexible, excellent shock absorption

Use Cases: Electronics, medical devices, small instruments

Best for: Medium to heavy items that need both cushioning and structural support

Pros: Closed-cell, rigid, moisture- and chemical-resistant

Use Cases: Automotive components, appliances, tools, industrial equipment

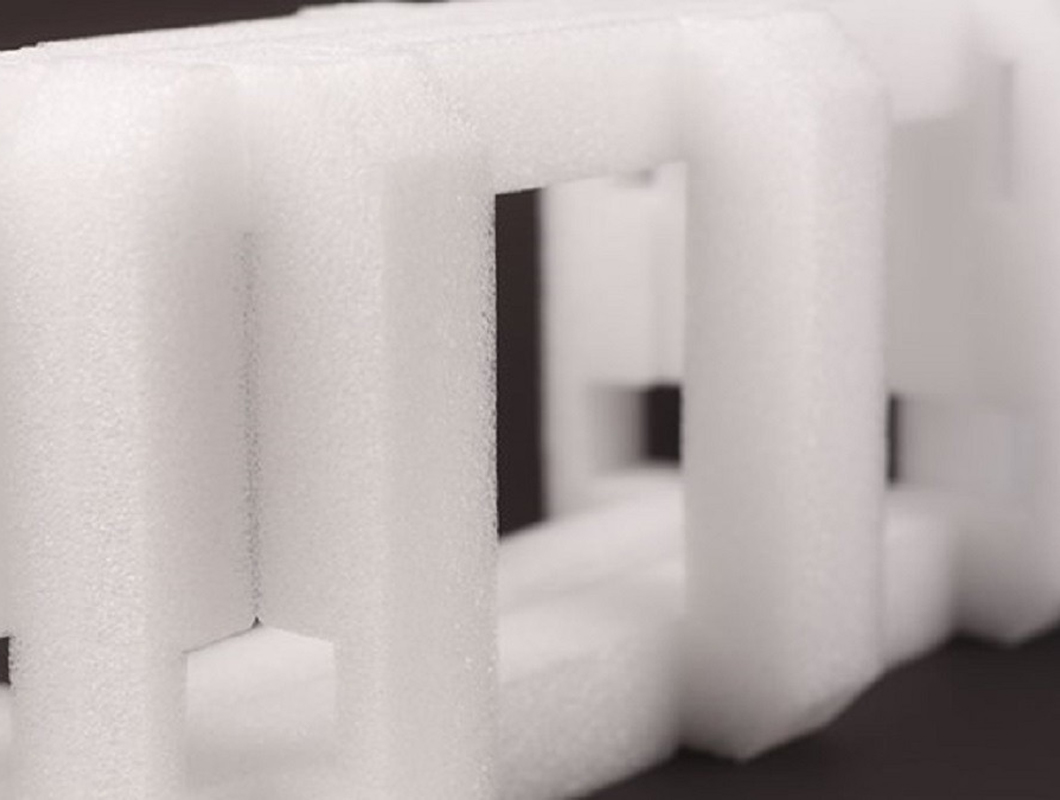

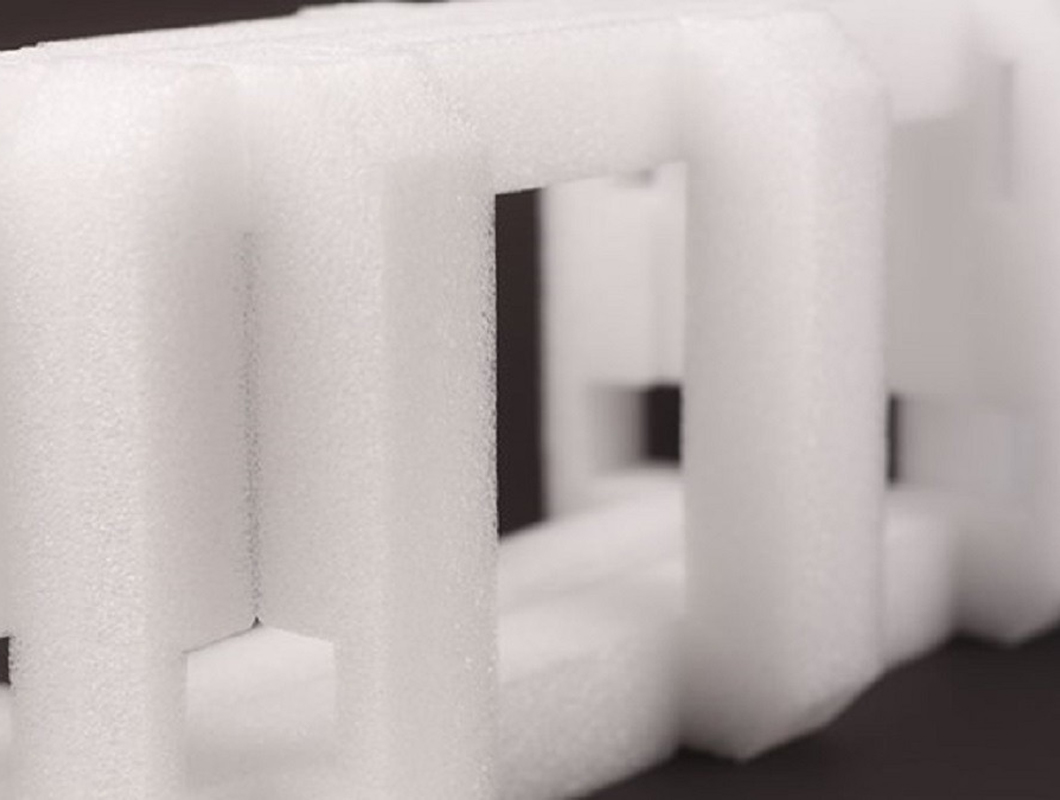

Expanded Polyethylene (EPE)

Best for: Versatile applications, one-way or returnable packaging, and products requiring"Class A"surface protection

Pros: Class A surface finish, high strength-to-weight ratio, easily fabricated into complex shapes

Use Cases: Protective packaging, case inserts, medical packaging, crates and road cases

Best for: High-end packaging that requires both durability and a premium appearance

Pros: Smooth surface, long-lasting performance, excellent shock resistance

Use Cases: Branded packaging, specialty case inserts, military and medical transport packaging

Expanded Polypropylene (EPP)

Best for: Reusable or returnable packaging and heavy industrial products

Pros: Exceptional impact resistance, strong recovery, highly reusable

Use Cases: Returnable containers, robotics, aerospace components

Anti-Static Foams (ESD-Safe: PE, PU, Zote)

Best for: Sensitive electronics and static-sensitive assemblies

Pros: Prevents electrostatic discharge during handling and transit

Use Cases: PCBs, semiconductors, sensors, electronic modules

How TOPSUN Foam Helps You Reduce Damage Claims

TOPSUN isn't just a foam supplier—we're your packaging engineering partner. Our team guides you through a proven process to develop a custom solution that performs reliably in real-world conditions:

●We analyze your product, how it's shipped, and where protection is most needed

●We compare foam types based on cushioning, compression strength, durability, moisture resistance, and cost.

●We design inserts, supports, and assemblies that secure your product, absorb impact, and provide targeted structural support.

●We can supply prototype samples for fit checks or conduct drop testing when needed.

Whether you need low-volume custom kits or high-volume production runs, we deliver precise, production-ready foam components that meet your specifications and schedule.

Don't Let Packaging Be the Weakest Link

This is the ideal moment to improve your packaging. You don't need a complete redesign—just the right foam engineered to protect your product.

Ship smarter with TOPSUN. Contact us today for a free consultation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu