Foam density remains a core factor in both packaging and product design. In 2026, its importance is greater than ever, as dimensional (DIM) weight pricing continues to drive shipping costs and performance expectations for impact protection and durability keep rising.

Choosing the right foam goes far beyond basic cushioning. Density influences overall foam weight, package size, freight expenses, fabrication flexibility, and long-term performance throughout the supply chain. By understanding how density works—and how it relates to foam type, firmness, and structural design—teams can eliminate excess volume while delivering stronger, more reliable protection.

How Foam Density Influences Packaging Performance

Foam density describes how much material is contained within a given volume, and it directly impacts how foam performs in protective packaging applications. Key performance factors affected by density include:

●Structural strength and durability

●Required thickness for effective protection

●Overall package size and foam weight

●Long-term resilience under repeated handling and transport

Higher density doesn't automatically translate to better protection. In many cases, overly dense foam increases weight and package dimensions without delivering meaningful performance gains. When properly matched to the application, lower-density shock-absorbing foams can provide equal—or even superior—protection.

The objective is to select a foam density that supports the product load, manages impact energy, and minimizes overall package volume.

Density, Firmness, and Foam Type Are Distinct Variables

Density is often mistaken as a direct measure of firmness, but true firmness is defined by Indentation Force Deflection (IFD)—the force required to compress foam by a specified percentage.

By evaluating density and IFD together, engineers gain greater control over packaging performance. In many designs, a higher IFD allows the desired firmness to be achieved at a lower density, resulting in:

●Thinner foam profiles

●Reduced package dimensions

●Lower DIM weight charges

●Consistent impact protection

This strategy is especially effective when developing custom foam inserts and protective packaging solutions for high-value or fragile products, where performance and shipping efficiency must work hand in hand.

Why Foam Density Has a Direct Impact on DIM Weight

Dimensional (DIM) weight pricing is driven by package volume—not actual weight. Even minor increases in carton dimensions can result in significant freight cost increases.

Foam that is overly dense or excessively thick can expand overall package size. On the other hand, foam that is too soft may require additional layers or oversized cavities to achieve adequate protection—producing the same outcome.

Optimizing foam density helps control:

●Carton size and footprint

●Foam weight and material consumption

●Long-term freight expenses

●Total packaging cost

In many applications, fine-tuning density selection delivers measurable reductions in shipping costs while maintaining—or improving—product protection.

Matching Density to Performance Enhances Protection

Foam performance under load directly determines its protective capability. Cushioning curves illustrate how various foam types respond to impact forces, making them essential tools when designing foam packaging, case inserts, and dunnage.

Foam density affects fabrication precision, material efficiency, carton dimensions, and overall packaging performance from production through transit. When density, IFD, and cushioning characteristics are aligned with product weight and handling conditions, foam provides more predictable results—leading to:

●Enhanced shock absorption

●Reduced damage rates

●Greater shipment consistency

●Extended service life for reusable packaging

True protection comes from selecting the right foam solution—not simply increasing material volume.

Application-Specific Density Considerations

Protective Foam Packaging and Dunnage

Shipping applications demand a balance between impact protection and space efficiency. Selecting the appropriate foam density helps minimize carton dimensions while maintaining reliable cushioning performance.

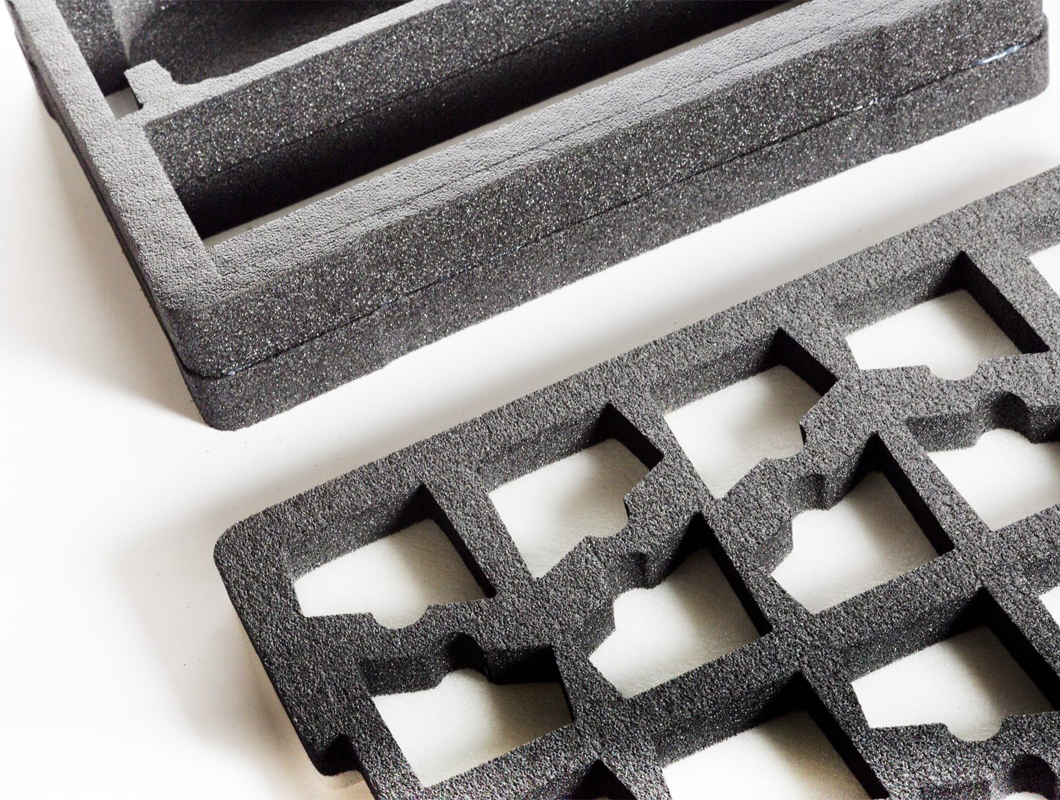

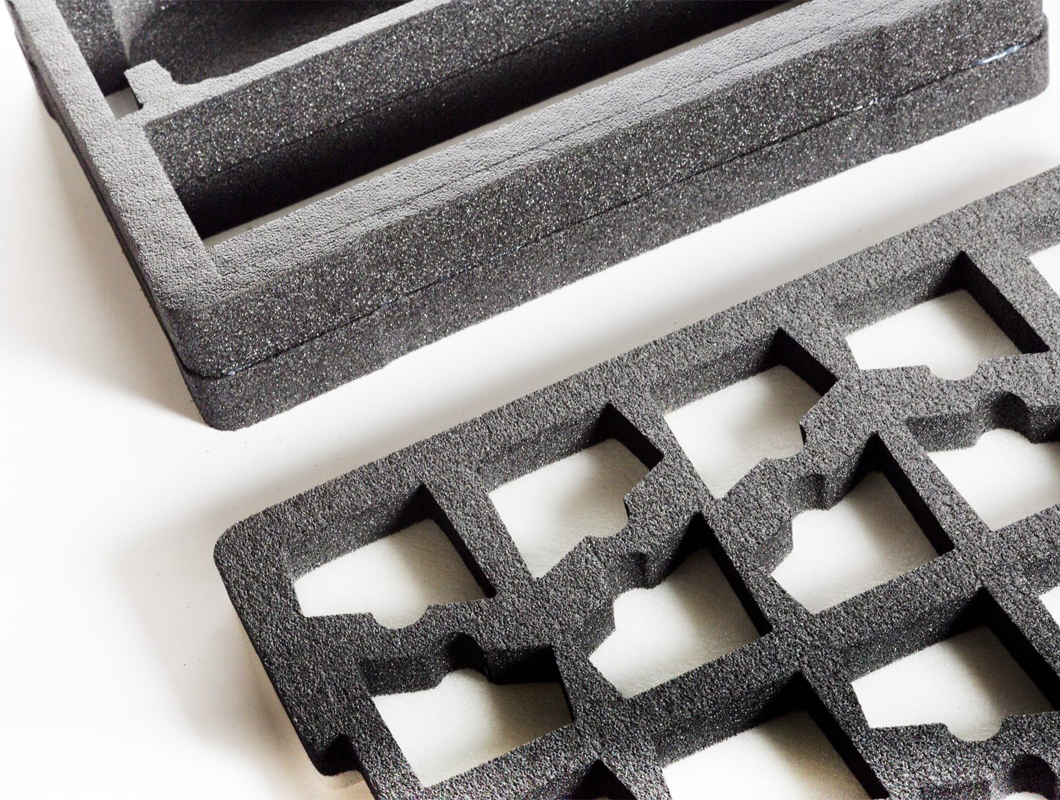

Custom Foam Inserts and Case Inserts

Precision-cut foam inserts must deliver accurate fit and consistent protection. Density directly influences product retention, case durability, and overall presentation quality.

Medical, Electronics, and OEM Applications

Medical devices, electronics, and OEM components often require controlled compression behavior, anti-static properties, and long-term material stability. These applications frequently use layered constructions that combine multiple foam densities to optimize performance.

Industrial, Automotive, and Marine Applications

Durable closed-cell foams such as XLPE, EPP, and polyethylene are commonly used in automotive parts, reusable packaging, and marine environments. These materials provide water resistance, thermal insulation, and long-term durability under demanding conditions.

Foam Density and Material Selection

Foam materials behave differently even at similar densities. Common options include:

●Polyurethane foams for cushioning and comfort applications

●Closed-cell foams such as polyethylene, EPP, and XLPE for protection and moisture resistance

●Expanded polystyrene (EPS) for rigid insulation and temperature-controlled shipping

●Anti-static foams for electronics and sensitive components

Understanding how each foam type performs enables engineers to select density ranges that achieve protection goals without adding unnecessary bulk.

Selecting Density for Manufacturing

Foam density should always be evaluated alongside fabrication requirements, as not all foam materials support the same production processes.

TOPSUN offers a full range of fabrication capabilities, including:

●CNC routing and laser cutting

●Die cutting and waterjet cutting

●Lamination and multi-layer assembly

●Short-run prototyping and full-scale production

Aligning foam density with fabrication methods early in the design process helps prevent costly redesigns and ensures consistent quality from prototype through production.

Foam Density Continues to Enable Smarter Packaging in 2026

When foam density is selected with fabrication processes and handling conditions in mind, packaging systems become more efficient and repeatable. This approach delivers:

●Reduced carton sizes with consistent structural support

●Improved product stability during transit

●Cleaner fabrication with tighter insert tolerances

●More efficient material usage at production scale

True packaging performance comes from engineering foam as part of a complete system—from manufacturing through final delivery.

Turn Foam Density Into a Cost Advantage

Optimized foam density helps manage package dimensions, minimize DIM weight charges, and provide reliable protection throughout transit.

TOPSUN partners with engineering and packaging teams to evaluate materials, refine density ranges, and align foam performance with fabrication and shipping requirements—transforming foam selection into a measurable cost and performance advantage.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu