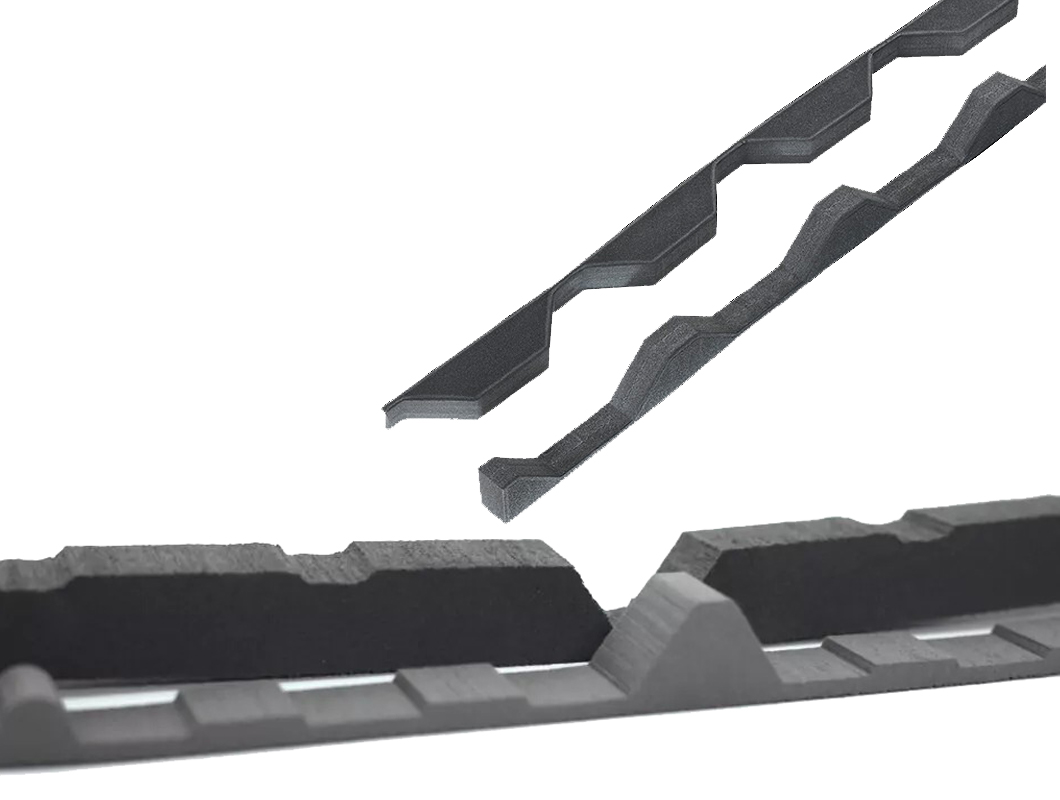

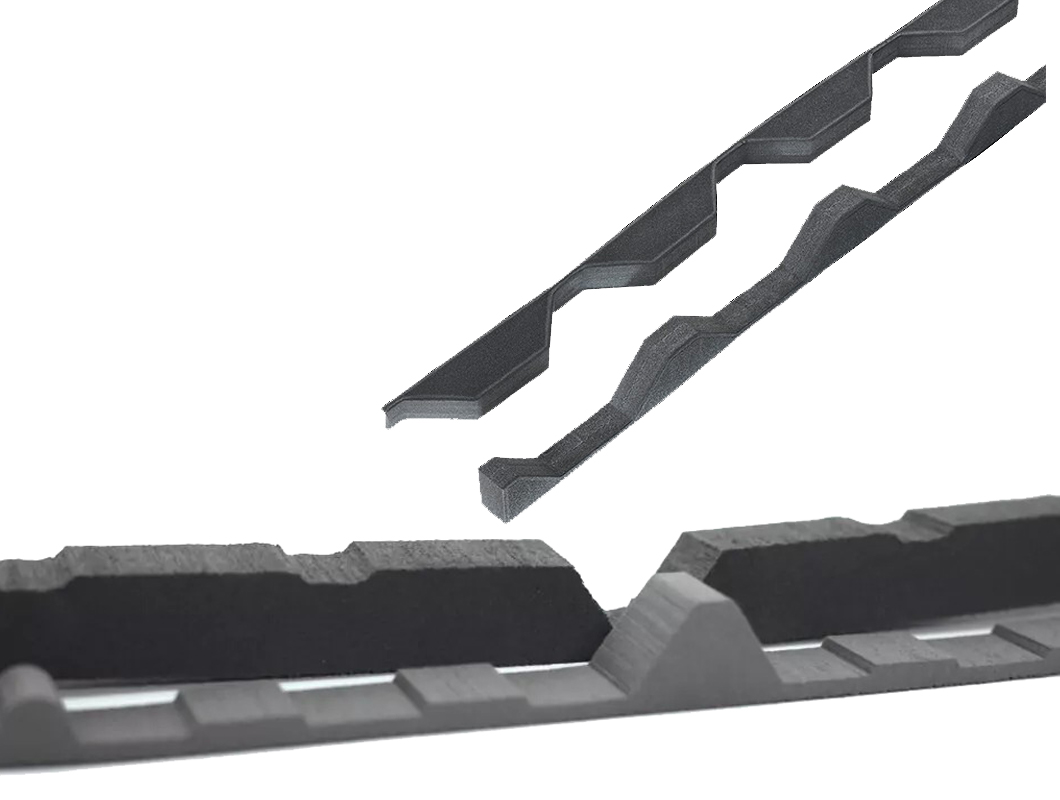

Our extruded crosslinked polyethylene (XLPE) foam is purpose-built for roof and sidewall closures, delivering reliable performance even in extreme climates. With its fine closed-cell structure, it offers exceptional weatherproofing to effectively seal gaps and joints in roofing and siding panels—keeping out moisture, debris, and pests. Lightweight yet durable, the crosslinked XLPE foam is also highly flexible, ensuring easy handling and quick installation on-site.

Press-Ready Materials for Roof Closure Strips:

●Local Production: Custom-sized sheets and rolls designed to meet your specifications and minimize material waste.

●Adhesive Applications: Available with rubber or acrylic pressure-sensitive adhesive (PSA) for easy bonding of weatherstripping to enclosure surfaces.

●Slitting: Wide rolls can be slit into precise, narrow widths tailored to your application needs.

●Level-Wound Spooling: Master rolls are converted into continuous custom-profile shapes in various widths and lengths for efficient processing and installation.

Utilizing Cross-Linked Polyethylene (XLPE) Foam for Building and Roof Closures

1. Introduction

In modern construction, closure materials must deliver exceptional sealing, insulation, and long-term durability. Cross-Linked Polyethylene (XLPE) foam, along with Neoprene and EPDM rubber, has emerged as a preferred choice for these demanding applications. Their fine closed-cell structures and excellent resistance to environmental stressors make them ideal for use in roof, wall, and structural closures. This document outlines their key advantages, typical applications, and their growing role within the building industry.

2. Properties of Cross-Linked Polyethylene Foam and Related Materials

These high-performance materials offer a unique combination of physical and chemical properties that make them well-suited for construction closure systems:

●Thermal Insulation: Low thermal conductivity enhances energy efficiency and interior comfort.

●Moisture Resistance: Closed-cell composition blocks water absorption, preventing mold and mildew.

●Durability: Resistant to aging, UV exposure, and environmental wear, ensuring long service life.

●Lightweight and Flexible: Easy to handle, cut, and fit without adding excess load to the structure.

●Chemical Resistance: Withstands exposure to common construction chemicals, solvents, and pollutants.

3. Applications in Building and Construction Closures

3.1 Roof Closures

▶Closure Strips: Used to seal gaps in metal roofing and sidewall assemblies, preventing leaks and air infiltration.

▶Foam Filler and Panel Opening Fillers: Provide a tight seal while supporting structural integrity.

▶Vented Options: Solutions such as MultiVent™ enable controlled airflow while retaining insulation performance.

▶Beveled Closures: Designed to fit diverse roofing profiles for a clean, secure installation.

3.2 Door and Window Seals

▶Foam Strips and Closure Profiles: Create airtight seals that enhance thermal performance and building efficiency.

▶Weatherstripping Solutions: XLPE foam and Neoprene materials help minimize air leakage, noise, and vibration.

3.3 HVAC Insulation and Ductwork

▶Thermal Barriers: Improve heating and cooling efficiency by reducing heat loss.

▶Acoustic Insulation: Minimize noise transmission and vibration within duct systems.

3.4 Concrete Expansion Joint Fillers

▶Foam Filler Strips: Absorb movement and prevent cracking in expansion joints.

▶Closure Profiles: Act as cushions between concrete sections, accommodating stress and structural shifts.

4. Industry Trends and Adoption of Foam Roof Closures

The adoption of XLPE foam, Neoprene, and EPDM rubber in construction continues to rise, driven by sustainability goals and stricter energy standards. Key developments include:

▶Green Building Initiatives: Certifications such as LEED (Leadership in Energy and Environmental Design)promote the use of energy-efficient, high-performance insulation materials like XLPE foam.

▶Regulatory Standards: Compliance with ASTM and ISO benchmarks reinforces the reliability of XLPE in architectural applications.

▶Manufacturing Advancements: Modern extrusion and crosslinking technologies enhance product precision, customization, and overall installation efficiency.

5. Why Source Roof Closure Foam Locally?

5.1 Reduced Lead Times and Costs

▶Faster material delivery minimizes project delays and downtime.

▶Avoids long international shipping schedules and uncertainties.

▶Eliminates additional expenses such as freight charges, tariffs, and customs fees.

5.2 Customization and Flexibility

▶Enables lower minimum order quantities (MOQs) and trial runs for new projects.

▶Offers tailored SKUs, sizes, and foam densities to meet specific application requirements.

Conclusion

Crosslinked Polyethylene (XLPE) Foam, Neoprene, and EPDM rubber provide reliable and high-performance solutions for building and roof closure applications. Their exceptional thermal insulation, moisture resistance, and long-term durability make them ideal for modern construction needs. As the demand for sustainable and energy-efficient materials continues to grow, these advanced foams and elastomers will remain essential to achieving superior building performance and environmental compliance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu