Ukuminyana kwegwebu kuhlala kuyisici esibalulekile kukho kokubili ukupakishwa nokwakhiwa komkhiqizo. Ngo-2026, ukubaluleka kwayo kukhulu kunangaphambili, njengoba intengo yesisindo se-dimensional (DIM) iqhubeka nokushayela izindleko zokuthumela kanye nokulindelwe kokusebenza kokuvikela umthelela nokuqina kuqhubeka nokukhuphuka.

Ukukhetha igwebu elifanele kudlulela ngalé kwe-cushioning eyisisekelo. Ukuminyana kuthonya isisindo segwebu eliphelele, usayizi wephakheji, izindleko zempahla, ukuguquguquka kokwakhiwa, nokusebenza kwesikhathi eside kulo lonke uchungechunge lokuhlinzeka. Ngokuqonda ukuthi ukuminyana kusebenza kanjani—nokuthi kuhlobana kanjani nohlobo lwegwebu, ukuqina, kanye nokwakheka kwesakhiwo—amaqembu angasusa ivolumu eyeqile kuyilapho eletha ukuvikeleka okuqinile, okuthembekile.

Ukuminyana Kwegwebu Kuthonya Kanjani Ukusebenza Kokupakisha

Ukuminyana kwegwebu kuchaza ukuthi kungakanani okuqukethwe kuvolumu enikeziwe, futhi kuthinta ngokuqondile indlela igwebu elisebenza ngayo ezinhlelweni zokupakisha ezivikelayo. Izinto zokusebenza ezibalulekile ezithintwa ukuminyana zihlanganisa:

●Amandla esakhiwo nokuqina

● Ugqinsi oludingekayo ukuze kuvikelwe ngempumelelo

● Usayizi wephakheji uwonke kanye nesisindo segwebu

●Ukuqina kwesikhathi eside ngaphansi kokuphathwa ngokuphindaphindiwe nokuthutha

Ukuminyana okuphezulu akuhumushi ngokuzenzakalelayo ekuvikelekeni okungcono. Ezimweni eziningi, igwebu eliminyene ngokweqile lenyusa isisindo kanye nobukhulu bephakheji ngaphandle kokuletha izinzuzo zokusebenza okunenjongo. Uma efaniswa kahle nohlelo lokusebenza, amagwebu abamba ukushaqeka aphansi anganikeza ukuvikeleka okulinganayo—noma okungcono kakhulu.

Inhloso ukukhetha ukuminyana kwegwebu elisekela ukulayishwa komkhiqizo, elilawula amandla omthelela, futhi linciphise ivolumu yephakheji iyonke.

Ukuminyana, Ukuqina, Nohlobo Lwegwebu Kuyizinto Eziguquguqukayo Ezihlukile

Ukuminyana kuvame ukwenziwa iphutha njengesilinganiso esiqondile sokuqina, kodwa ukuqina kwangempela kuchazwa yi-Indentation Force Deflection (IFD)—amandla adingekayo ukuze ucindezele igwebu ngephesenti elithile.

Ngokuhlola ukuminyana kanye ne-IFD ndawonye, onjiniyela bathola ukulawula okukhulu ekusebenzeni kokupakisha. Emiklamo eminingi, i-IFD ephakeme ivumela ukuqina okufiswayo ukuthi kuzuzwe ngokuminyana okuphansi, okuholela kulokhu:

● Amaphrofayili amagwebu amancane

●Ubukhulu bephakheji obuncishisiwe

● Amashaji esisindo se-DIM aphansi

●Ukuvikelwa komthelela okungaguquki

Leli su lisebenza kahle kakhulu lapho kwakhiwa ukufakwa kwegwebu langokwezifiso kanye nezixazululo zokupakisha ezivikelayo zenani eliphezulu noma imikhiqizo ebuthakathaka, lapho ukusebenza nokusebenza kahle komkhumbi kufanele kusebenze ngokubambisana.

Kungani Ukuminyana Kwegwebu Kunomthelela Oqondile Kusisindo se-DIM

Intengo yesisindo se-Dimensional (DIM) iqhutshwa umthamo wephakheji—hhayi isisindo sangempela. Ngisho nokwenyuka okuncane kobukhulu bamakhathoni kungaholela ekwenyukeni okukhulu kwezindleko zempahla.

Igwebu eliminyene ngokweqile noma eliwugqinsi ngokweqile linganweba usayizi wephakheji lilonke. Ngakolunye uhlangothi, igwebu elithambile kakhulu lingadinga izendlalelo ezengeziwe noma izimbotshana ezinkulu ukuze kuzuzwe ukuvikeleka okwanele—ukukhiqiza umphumela ofanayo.

Ukuthuthukisa ukuminyana kwegwebu kusiza ukulawula:

●Usayizi webhokisi nezinyathelo

● Isisindo segwebu nokusetshenziswa kwezinto ezibonakalayo

● Izindleko zezimpahla zesikhathi eside

●Isamba sezindleko zokupakisha

Ezinhlelweni eziningi, ukukhetha ukuminyana kokulungisa kahle kuletha ukuncipha okulinganisekayo ezindlekweni zokuthumela kuyilapho kugcinwa—noma ukuthuthukisa—ukuvikela umkhiqizo.

Ukuqhathanisa Ukuminyana Kokusebenza Kuthuthukisa Ukuvikelwa

Ukusebenza kwegwebu ngaphansi komthwalo kunquma ngokuqondile amandla ayo okuvikela. Amajika e-Cushioning abonisa indlela izinhlobo ezihlukahlukene zegwebu ezisabela ngayo kumandla omthelela, okuwenza abe amathuluzi abalulekile lapho uklama ukupakishwa kwegwebu, ukufakwa kwekesi, kanye nemfucumfucu.

Ukuminyana kwegwebu kuthinta ukunemba kokwenziwa, ukusebenza kahle kwezinto, ubukhulu bamakhathoni, nokusebenza kokupakisha sekukonke kusukela ekukhiqizeni ngokuhamba kwezokuthutha. Uma ukuminyana, i-IFD, kanye nezici zokunciphisa ziqondaniswe nesisindo somkhiqizo nezimo zokuphatha, igwebu linikeza imiphumela ebikezelwe—okuholela kulokhu:

●Ukumunca ukushaqeka okuthuthukisiwe

● Izinga lomonakalo elincishisiwe

●Ukungaguquguquki okukhulu kokuthunyelwa

● Impilo yesevisi enwetshiwe yokupakishwa okusebenziseka kabusha

Isivikelo sangempela sivela ekukhetheni isisombululo esifanele segwebu—hhayi nje ukwandisa umthamo wezinto ezibonakalayo.

Ukucabangela Ukuminyana Okuthile Kohlelo

I-Protective Foam Packaging kanye ne-Dunnage

Izinhlelo zokusebenza zokuthumela zidinga ibhalansi phakathi kokuvikela umthelela nokusebenza kahle kwesikhala. Ukukhetha ukuminyana kwegwebu elifanele kusiza ukunciphisa ubukhulu bebhokisi ngenkathi kugcinwa ukusebenza okuthembekile kokuguqa.

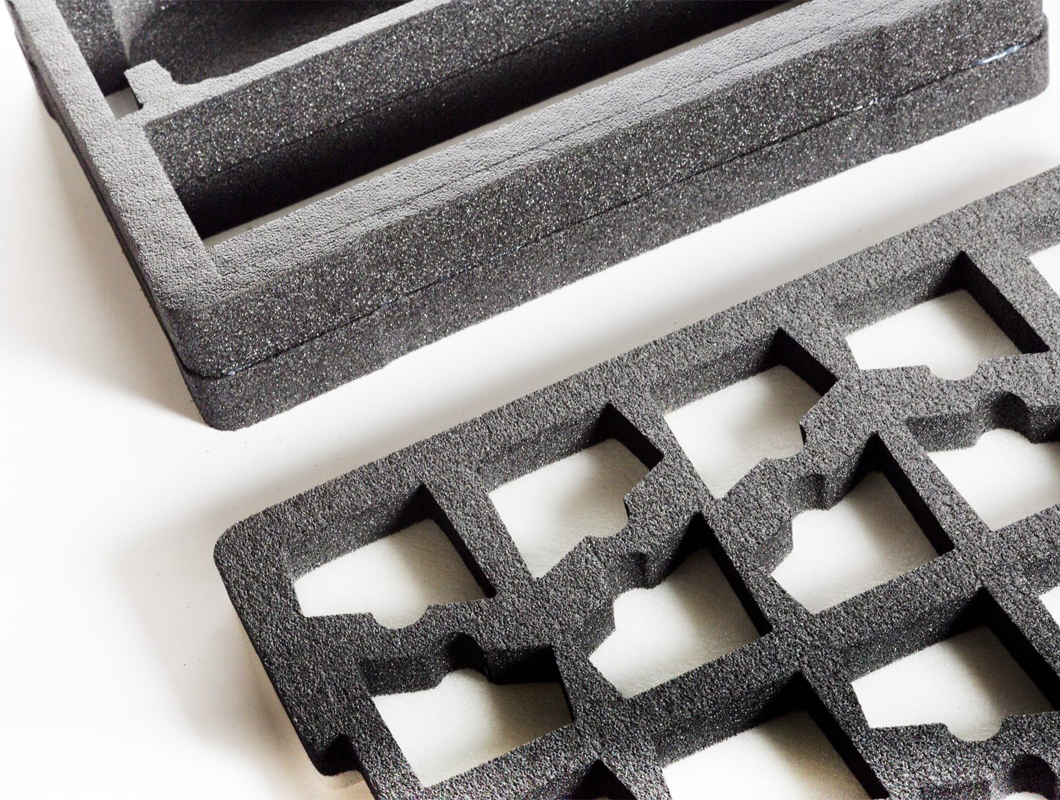

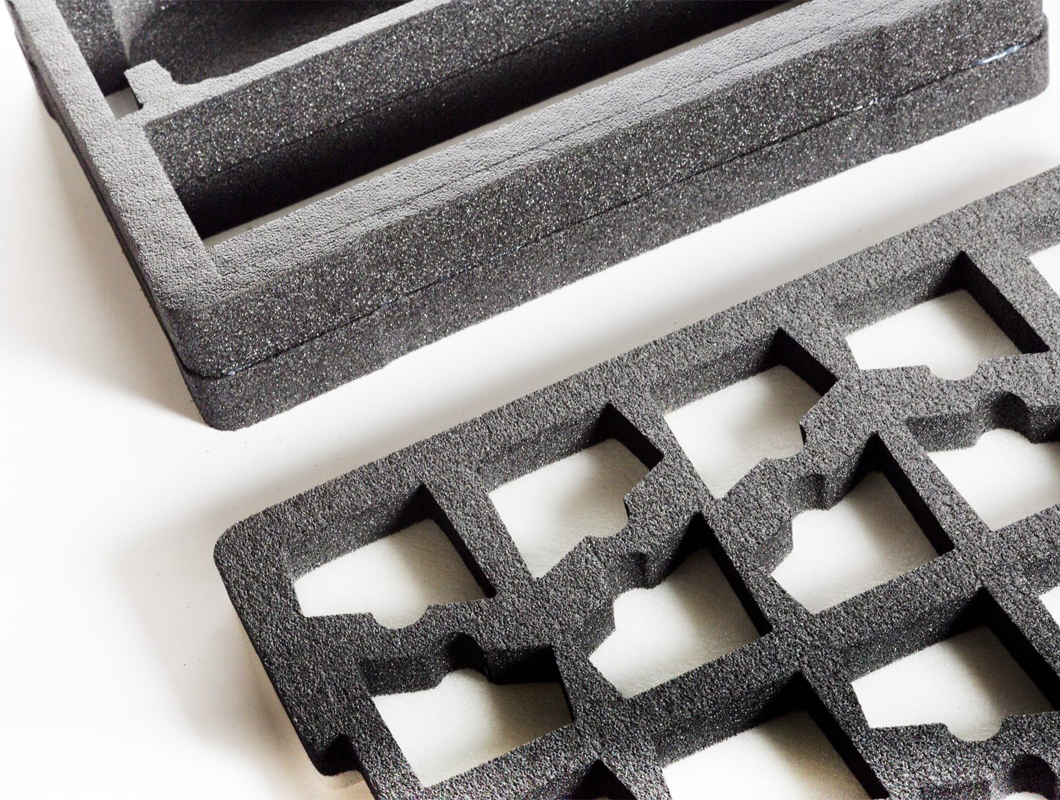

Ukufakwa Kwegwebu Ngokwezifiso Nokufakwa Kwekesi

Ukufakwa kwegwebu elisikwe ngokunemba kufanele kulethe ukulingana okunembile nokuvikelwa okungaguquki. Ukuminyana kuthonya ngokuqondile ukugcinwa komkhiqizo, ukuqina kwekesi, kanye nekhwalithi yokwethulwa iyonke.

Izicelo zezokwelapha, zikagesi, neze-OEM

Imishini yezokwelapha, izinto zikagesi, kanye nezingxenye ze-OEM ngokuvamile zidinga ukuziphatha kokuminyanisa okulawulwayo, izakhiwo eziphikisana ne-static, nokuzinza kwempahla yesikhathi eside. Lezi zinhlelo zokusebenza zivamise ukusebenzisa ukwakhiwa okufakwe izingqimba ezihlanganisa ukuminyana kwegwebu eliningi ukuze kuthuthukiswe ukusebenza.

Izicelo zezimboni, ezezimoto, nezasolwandle

Amagwebu amaseli avaliwe aqinile njenge-XLPE, i-EPP, ne-polyethylene avame ukusetshenziswa ezingxenyeni zezimoto, emaphaketheni asebenzisekayo kabusha, nasezindaweni zasolwandle. Lezi zinto zinikeza ukumelana kwamanzi, ukufakwa kwe-thermal, nokuqina kwesikhathi eside ngaphansi kwezimo ezinzima.

Ukuminyana Kwegwebu kanye Nokukhethwa Kwempahla

Izinto ze-Foam ziziphatha ngendlela ehlukile ngisho nasezinkingeni ezifanayo. Izinketho ezijwayelekile zifaka:

●Amagwebu e-polyurethane asetshenziselwa ukumisa nokududuza izicelo

●Amagwebu amaseli avaliwe njenge-polyethylene, i-EPP, ne-XLPE ukuze avikeleke futhi amelane nomswakama

● I-polystyrene enwetshiwe (i-EPS) yokugqumisa okuqinile kanye nokuthutha okulawulwa yizinga lokushisa

●Amagwebu e-Anti-static for electronics kanye nezingxenye ezibucayi

Ukuqonda ukuthi uhlobo lwegwebu ngalunye lusebenza kanjani lwenza onjiniyela bakwazi ukukhetha ububanzi bokuminyana obufinyelela imigomo yokuvikela ngaphandle kokwengeza inqwaba engadingekile.

Ukukhetha Ukuminyana Kokukhiqiza

Ukuminyana kwegwebu kufanele ngaso sonke isikhathi kuhlolwe ngokuhambisana nezidingo zokwenziwa, njengoba akuzona zonke izinto zegwebu ezisekela izinqubo zokukhiqiza ezifanayo.

I-TOPSUN inikeza uhla olugcwele lwamakhono okwenza, okuhlanganisa:

● Umzila we-CNC nokusika kwe-laser

● Ukusika i-Die nokusika i-waterjet

● Lamination kanye multi-layer umhlangano

●I-prototyping yesikhathi esifushane kanye nokukhiqizwa kwesikali esigcwele

Ukuqondanisa ukuminyana kwegwebu nezindlela zokwenziwa ekuqaleni kwenqubo yokuklama kusiza ukuvimbela ukuklama kabusha okumba eqolo futhi kuqinisekisa ikhwalithi engaguquki kusukela ku-prototype ngokukhiqiza.

Ukuminyana Kwegwebu Kuyaqhubeka Nokunika amandla Ukupakisha Okuhlakaniphile ngo-2026

Uma ukuminyana kwegwebu kukhethwa kucatshangelwa izinqubo zokwenziwa kanye nezimo zokuphatha, amasistimu okupakisha asebenza kahle futhi aphindaphindeka. Le ndlela inikeza:

●Osayizi abancishisiwe bamakhathoni anosekelo lwesakhiwo olungaguquki

●Ukuqina komkhiqizo okuthuthukisiwe ngesikhathi sokuthutha

●Ukwenziwa okuhlanzekile okubekezelela ukufakwa okuqinile

● Ukusetshenziswa kwempahla esebenza ngempumelelo esikalini sokukhiqiza

Ukusebenza kokupakisha kwangempela kuvela kugwebu lobunjiniyela njengengxenye yesistimu ephelele—kusuka ekukhiqizeni kuye ekulethweni kokugcina.

Guqula Ukuminyana Kwegwebu Kube Inzuzo Yezindleko

Ukuminyana kwegwebu okulungiselelwe kusiza ukuphatha ubukhulu bephakheji, ukunciphisa amashaji esisindo se-DIM, futhi kunikeze ukuvikeleka okuthembekile kukho konke ukuhamba.

I-TOPSUN ibambisene nonjiniyela namathimba okupakisha ukuze bahlole izinto ezisetshenziswayo, bacwengisise ububanzi bokuminyana, futhi baqondise ukusebenza kwegwebu nezimfuneko zokwenziwa nokuthutha—ukuguqula ukukhetha kwegwebu kube yizindleko ezilinganisekayo kanye nenzuzo yokusebenza.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu