When it comes to combining lightweight protection, thermal insulation, and structural strength, few materials perform as well as beaded foam. Widely used in protective packaging, coolers, automotive parts, and construction panels, beaded foams offer exceptional versatility across industries.

At TOPSUN Foam, we specialize in working with a range of beaded foams—primarily expanded polypropylene (EPP), expanded polyethylene (EPE), and, in select applications, expanded polystyrene (EPS)—to deliver custom-fabricated solutions tailored to each customer's needs.

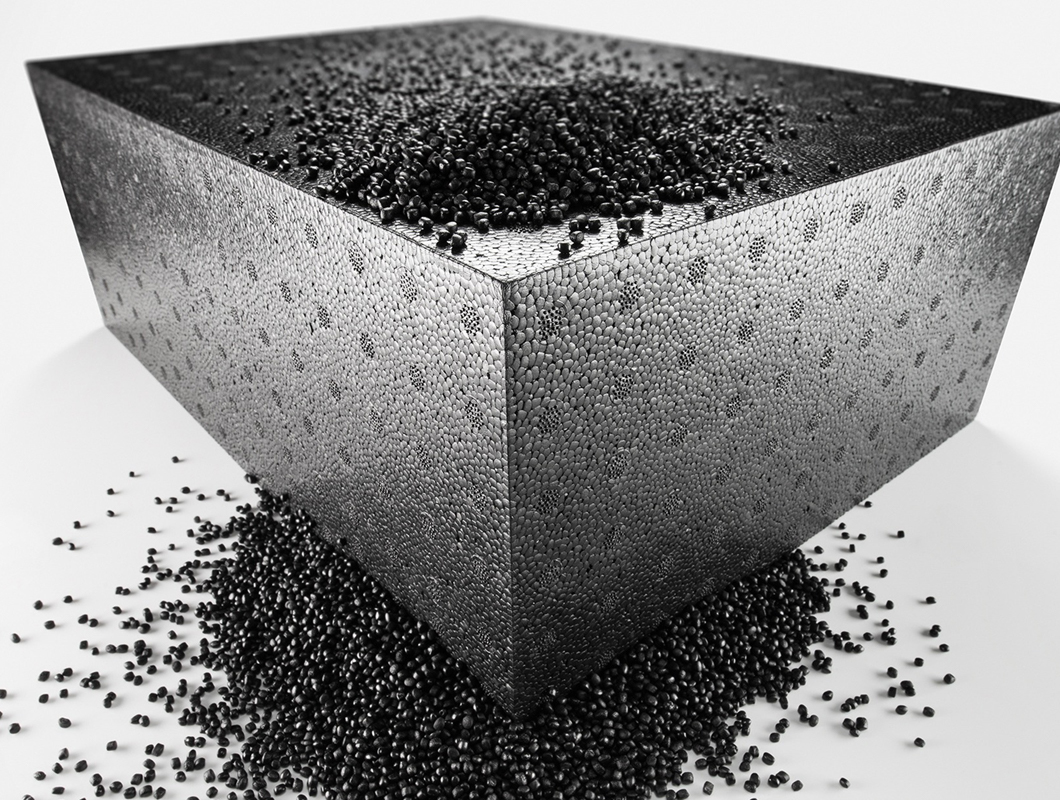

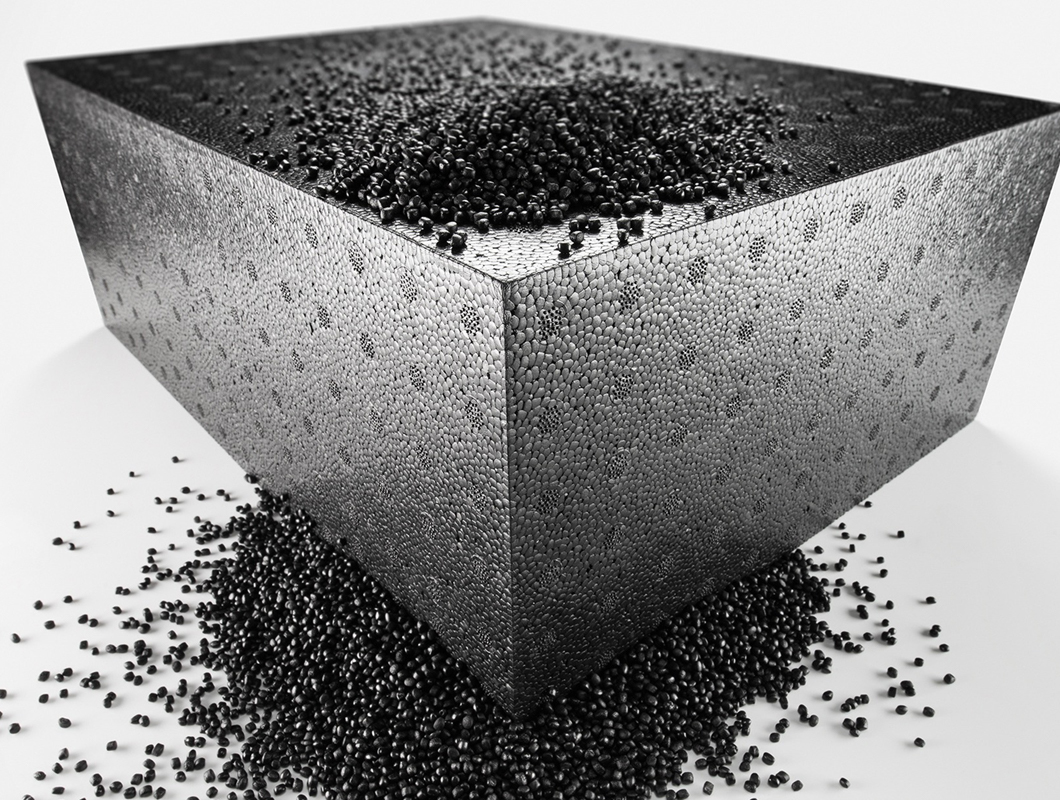

What Is Beaded Foam?

Beaded foam is a class of lightweight, closed-cell thermoplastics made by expanding pre-formed polymer beads with steam and pressure. These beads fuse together inside a mold, creating a strong, solid structure with an outstanding strength-to-weight ratio.

Unlike extruded foams, which are formed in continuous sheets, beaded foams are built from thousands of individual cells that bond during molding. This unique structure provides excellent energy absorption, dimensional stability, and thermal insulation, making beaded foam ideal for applications requiring impact protection and temperature resistance.

How Beaded Foam Is Made

The production of beaded foam involves several key steps:

●Pre-Expansion

Polymer beads (often containing a blowing agent such as pentane) are expanded with steam in a pre-expander, increasing their volume many times over.

●Aging/Conditioning

The expanded beads are stored in ventilated silos, allowing air to replace the blowing agent and equalize internal pressure—an essential step for long-term stability.

●Molding

The conditioned beads are placed in a mold and re-exposed to steam, which causes further expansion and fusion into a solid block or custom shape.

●Cooling and Ejection

Once formed, the part is cooled, removed from the mold, and may undergo secondary processes such as trimming, cutting, CNC routing, or lamination.

While each type of beaded foam has its own manufacturing parameters, this core process remains consistent across materials.

Expanded Polypropylene (EPP)

EPP delivers superior toughness and flexibility compared to EPS, making it one of the most durable beaded foams available. Known for its outstanding energy absorption and ability to spring back after compression, EPP excels in applications involving dynamic loads, repeated impacts, or drop testing. It is resistant to water, chemicals, and solvents, while maintaining performance across a wide temperature range.

Because of these properties,EPP is widely used in reusable packaging, automotive interiors (such as bumper cores, door panels, and headrests), and custom dunnage. It also offers sustainability benefits, thanks to its reusability and recyclability, which extend its service life. Although EPP generally costs more than EPS, the performance advantages often outweigh the higher upfront investment, particularly in heavy-duty or high-performance applications.

Expanded Polyethylene (EPE)

EPE is the softest and most flexible of the common beaded foams, valued for its cushioning and vibration-dampening capabilities. Its pliable structure makes it especially effective for protecting delicate, lightweight items. The closed-cell composition provides resistance to moisture and many chemicals, supporting reliable use in electronics packaging, medical device shipping, and flotation aids.

While EPE does not have the rigidity or structural strength of EPS or EPP, this softness is an advantage when gentle protection is required. It can also be thermoformed, laminated, or fabricated into custom shapes with ease. Another key benefit is its Class A surface finish, which makes it a strong choice when protecting product appearance or surface quality is critical.

Expanded Polystyrene (EPS)

EPS is one of the most common and cost-effective beaded foams. Manufactured by expanding and fusing polystyrene beads with steam, it produces a lightweight, rigid, and highly insulative material. Its closed-cell structure provides excellent thermal resistance and moisture protection, making it a go-to solution for cold-chain packaging, building insulation, and protective packaging for electronics and consumer goods.

However, EPS lacks the flexibility and recovery properties of EPP and EPE, so it is best suited for static applications where rigidity and thermal performance are more important than impact recovery. Because EPS is relatively brittle, it is not ideal for repeated impact or vibration-heavy environments.

The Benefits of Beaded Foam

Lightweight Strength

Beaded foams combine low weight with exceptional strength, delivering an excellent strength-to-weight ratio. This makes them ideal where weight reduction is essential without sacrificing durability or performance.

Thermal Insulation

Their closed-cell structure provides strong thermal resistance. EPS remains a leading choice in cold-chain packaging and building insulation, while EPP and EPE are also highly effective options for temperature-sensitive applications.

Shock Absorption

EPP and EPE are particularly effective at absorbing impact and regaining shape after compression, making them well suited for applications involving repeated drops or dynamic forces.

Moldability and Customization

Beaded foams can be molded into intricate shapes or precisely cut with CNC and hot-wire processes, allowing for highly tailored inserts, parts, and components.

Moisture and Chemical Resistance

The closed-cell composition resists water absorption, chemicals, and many solvents—an advantage for outdoor, automotive, and medical uses.

Reusability and Recyclability

EPP stands out for its ability to endure repeated use, extending product life cycles and offering a more sustainable solution through reusability and recyclability.

Custom Beaded Foam Fabrication with TOPSUN

At TOPSUN Foam, we provide complete beaded foam fabrication services designed around your unique product, packaging, or industrial requirements. From precision-cut EPS blocks to complex molded EPP components, our team supports you through material selection, prototyping, and full-scale production.

Our Capabilities Include:

●CNC contour cutting

●Hot-wire cutting

●Lamination and adhesive bonding

●Assembly and kitting

●Custom mold tooling and part fabrication

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu