Acoustic Foam: Intelligent Sound Management for Improved Environments

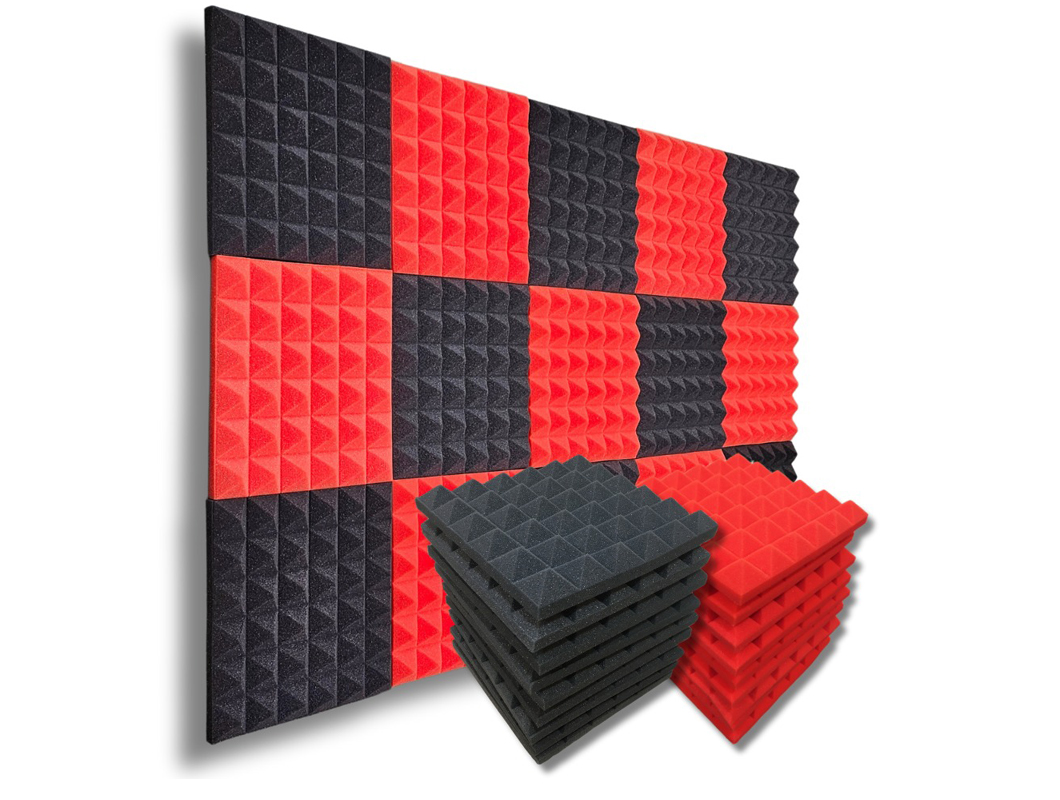

Acoustic foam is a specialized sound-absorbing material engineered to enhance the acoustic performance of enclosed spaces. It minimizes sound reflections, reverberation, and unwanted background noise to create clearer, more balanced sound quality. Unlike standard foam, acoustic foam features engineered surface patterns—such as wedges, pyramids, or egg crate designs—that increase surface area and improve sound absorption efficiency.

This versatile material is commonly used in recording studios, offices, home theaters, and industrial facilities where noise control is critical. Its lightweight composition, easy installation, and customizable designs make it a top choice for both professionals and hobbyists. Whether applied to walls, ceilings, or equipment panels, acoustic foam helps create a cleaner, more controlled sound environment.

In this article, we'll discuss its key properties, benefits, common applications, and important factors to consider when selecting the right acoustic foam for your needs.

1. Characteristics of Acoustic Foam

Acoustic foam is distinguished by its unique composition and structure. Typically made from open-cell polyurethane or melamine foam, it allows sound waves to penetrate and dissipate within the material, effectively reducing noise and echo. The foam’s geometric surface patterns—such as wedges, pyramids, or egg crate designs—help scatter and diffuse sound energy for greater acoustic control.

Key factors like density, thickness, and shape influence how efficiently the foam absorbs sound across different frequencies. Most acoustic foams are also fire-retardant and come in a range of colors and sizes to meet various aesthetic and performance requirements. They are lightweight and easy to install using adhesives, clips, or peel-and-stick backing.

Key Features:

●Open-cell structure for effective sound absorption

●Fire-retardant material

●Geometric surface patterns for sound diffusion

●Lightweight and easy to handle

●Available in custom sizes

●Multiple color options

2. Benefits of Acoustic Foam

Acoustic foam offers a range of practical benefits for effective sound control. Its primary advantage is reducing unwanted echoes and background noise, resulting in a clearer, more balanced acoustic environment—ideal for musicians, podcasters, streamers, and content creators. In office settings, it enhances speech clarity and minimizes distractions, improving focus and communication.

The material also helps eliminate flutter echoes and standing waves that can distort sound quality. Compared to structural acoustic treatments, acoustic foam is more affordable and requires no modifications to existing walls or ceilings. It's easy to install or remove without causing surface damage.

Additionally, some acoustic foams provide mild thermal insulation and moisture resistance, making them suitable for a variety of environments, including humid areas.

Key Benefits:

●Reduces echo and background noise

●Enhances sound clarity

●Simple, non-destructive installation

●Cost-effective solution

●Helps control flutter echoes and standing waves

●Offers optional insulation and moisture resistance

3. Applications of Acoustic Foam

Acoustic foam is highly versatile and used across a wide range of environments—from personal spaces to professional and industrial settings. In recording studios and control rooms, it helps achieve accurate sound by minimizing reflections and distortion. Home theaters use acoustic foam panels to improve audio clarity and enhance the immersive experience.

In offices and call centers, acoustic foam reduces noise transfer between workstations, fostering better concentration and communication. It's also widely used in classrooms, rehearsal spaces, gaming setups, and streaming rooms to improve speech clarity and reduce unwanted background noise.

In industrial applications, acoustic foam is installed in machinery enclosures, server rooms, and soundproof booths to lower noise levels and support compliance with safety standards. Within transportation, it's used in vehicle cabins, aircraft interiors, and engine compartments to minimize cabin noise and vibration.

Common Applications:

●Recording studios and control rooms

●Home theaters and entertainment spaces

●Office and call center environments

●Classrooms and rehearsal rooms

●Machinery enclosures and server rooms

●Vehicle and aircraft interiors

4. Considerations and Limitations

While acoustic foam offers many advantages, it also has certain limitations to consider. It is primarily effective at absorbing mid- to high-frequency sounds but performs less efficiently with low-frequency noise unless paired with bass traps or other acoustic treatments. For full soundproofing, acoustic foam should be used alongside materials like mass-loaded vinyl or dense sound barriers.

Fire safety is another key factor. Although many acoustic foams are fire-retardant, not all products meet commercial building codes—so it's important to verify certifications before installation.

Over time, the foam may degrade when exposed to direct sunlight or high humidity. Proper installation also plays a role in longevity, as low-quality adhesives can cause panels to detach over time.

Key Considerations:

●Not designed for complete soundproofing

●Limited low-frequency absorption

●Fire safety and certification requirements

●Susceptible to UV and moisture damage

●Adhesive quality affects long-term performance

FAQs about Acoustic Foam

Q1: Does acoustic foam block sound?

A1: No. Acoustic foam absorbs sound within a room but does not block noise from entering or leaving the space.

Q2: Where should I install acoustic foam panels?

A2: Place panels behind speakers, at first reflection points, and on ceilings or upper walls to maximize sound absorption.

Q3: Can I install acoustic foam myself?

A3: Yes. Most acoustic foam panels are lightweight and designed for easy, do-it-yourself installation using adhesive or mounting strips.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu