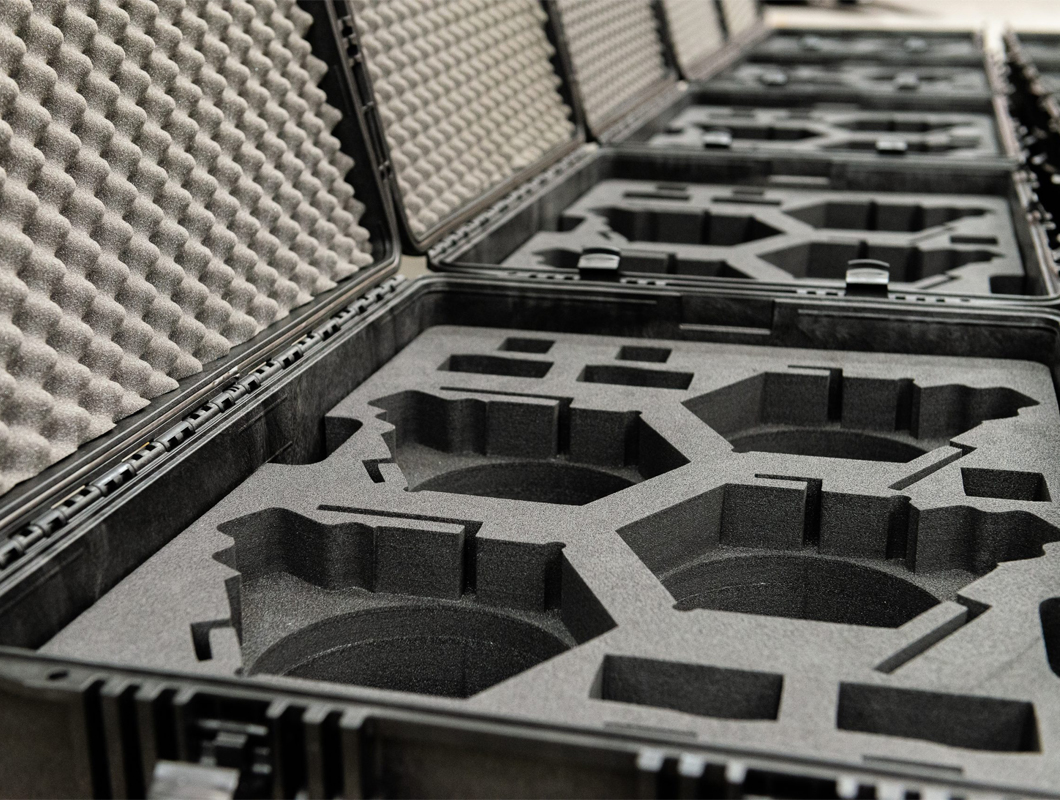

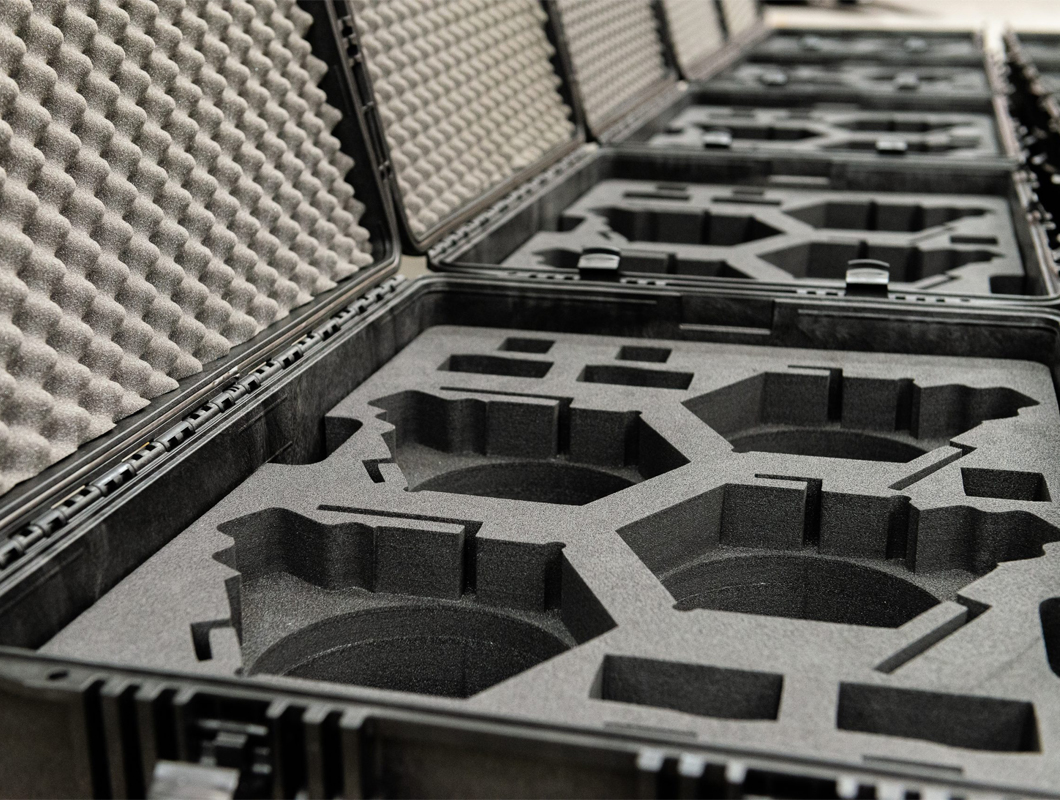

Precision packaging is vital for luxury goods and sensitive electronics. These premium products demand more than attractive presentation—they require engineered protection that keeps every item safe and perfectly positioned. Custom foam inserts deliver exactly that, offering secure fit, impact resistance, and an elevated unboxing experience. With advanced foam conversion capabilities, Ramfoam designs and manufactures tailored inserts that ensure high-value items reach their destination in flawless condition.

The Importance of Custom Foam Inserts in Premium Packaging

Luxury products deserve packaging that delivers both visual appeal and reliable protection. Custom foam inserts help achieve this balance by preventing transit damage, minimizing vibration, and presenting each item in a refined, organized manner. Whether for electronics, luxury goods, or delicate components, these inserts ensure every product stays securely in place—reinforcing the brand’s premium image and enhancing the unboxing experience.

TOPSUN designs and manufactures custom foam inserts using Polyethylene (PE) Foam and Polyurethane (PU) Foam—two high-performance materials suited for diverse packaging needs. PE Foam provides superior shock absorption along with chemical and moisture resistance, offering a combination of durability and a polished finish ideal for luxury goods. PU Foam, meanwhile, is soft, flexible, and adaptable—perfect for intricate inserts that need to contour to irregular shapes or cushion sensitive electronics and precision instruments.

TOPSUN's Advanced Foam Conversion Expertise

At TOPSUN, our state-of-the-art foam conversion capabilities distinguish us as a leader in premium packaging solutions. Using precision CNC technology, we create custom inserts with accurate, repeatable cuts tailored to each product's exact specifications. This precision enables us to produce intricate shapes and fine details, ensuring everything—from luxury cosmetics to sensitive electronic devices—fits seamlessly and securely.

Our comprehensive foam conversion process incorporates a range of specialised techniques to accommodate diverse packaging requirements, from delicate small parts to large, durable products. We offer multi-layered inserts, die-cut components, and custom-moulded designs, empowering brands with complete flexibility to achieve both aesthetic appeal and functional protection in their packaging.

The Importance of Tailored Packaging for Premium Products

Every luxury or high-end product comes with its own unique protection and presentation needs. At TOPSUN, our customised foam conversion approach ensures each insert is precisely engineered to match a product's dimensions, fragility, and performance requirements. This level of precision goes beyond aesthetics—guaranteeing that every item arrives in perfect condition and upholds the brand's premium reputation.

Our deep material expertise allows us to support a wide range of industries. Polyethylene Foam is available with antistatic, conductive, and flame-retardant options, making it ideal for sensitive electronics and components that demand added safety features.Polyurethane Foam, with its superior flexibility and cushioning performance, is perfectly suited for delicate items requiring gentle handling and dependable impact protection.

Applications of Custom Foam Inserts in Luxury and Electronics Packaging

TOPSUN's custom foam packaging solutions are trusted across industries where both protection and presentation are critical.

Luxury Goods

For premium products such as watches, jewelry, cosmetics, and collectibles, custom foam inserts provide a perfect balance of aesthetics and function—offering precision fit, impact protection, and a sophisticated unboxing experience that reflects brand excellence.

Electronics and Sensitive Equipment

For high-value electronics and delicate instruments, our foam inserts deliver superior cushioning, vibration control, and static protection. Each insert is engineered to keep components secure during handling and transit, reducing the risk of damage and ensuring flawless performance upon arrival.

Sustainability and Quality Assurance

At TOPSUN, sustainability is integral to our manufacturing process. We offer eco-friendly, recyclable foam materials that help brands reduce environmental impact without compromising on quality or performance. Both Polyethylene Foam and Polyurethane Foam are available in recyclable options, allowing clients to align with their sustainability goals while maintaining premium packaging standards.

In addition, our rigorous quality control procedures ensure every foam insert meets strict standards for precision, durability, and safety. With TOPSUN, brands can be confident that their products are protected by packaging that performs reliably and presents beautifully.

FAQs

Why should I use custom foam inserts for luxury packaging?

Custom foam inserts provide both protection and presentation. They ensure each product fits securely within its packaging, preventing damage during transit while enhancing the unboxing experience and reflecting the brand's premium quality.

What materials are used in Ramfoam's custom inserts, and how are they chosen?

TOPSUN uses high-performance materials such as Polyethylene (PE) Foam and Polyurethane (PU) Foam. The selection depends on each product's needs—PE Foam offers strength, moisture resistance, and durability, while PU Foam provides flexibility and cushioning for delicate or irregularly shaped items.

How does TOPSUN ensure quality and precision in foam insert production?

Through advanced CNC foam conversion technology and strict quality control, TOPSUN ensures every insert is manufactured with exact precision, consistent performance, and a flawless finish that meets industry standards.

Conclusion

For brands seeking to elevate their packaging and deliver products in perfect condition, TOPSUN's custom foam inserts are the ideal choice. Combining advanced foam conversion expertise, premium materials like PE and PU Foam, and a strong commitment to sustainability, TOPSUN helps high-end brands protect, present, and enhance their products with confidence. Explore our luxury foam packaging solutions and discover how we can help strengthen your brand's reputation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu