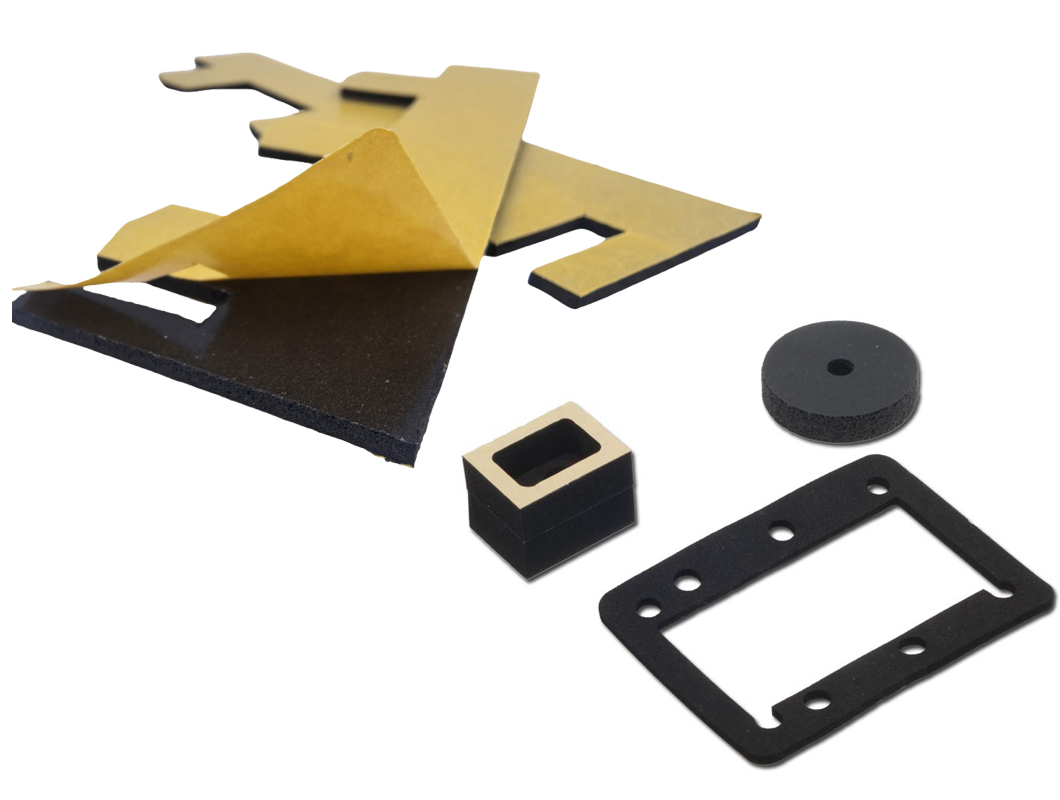

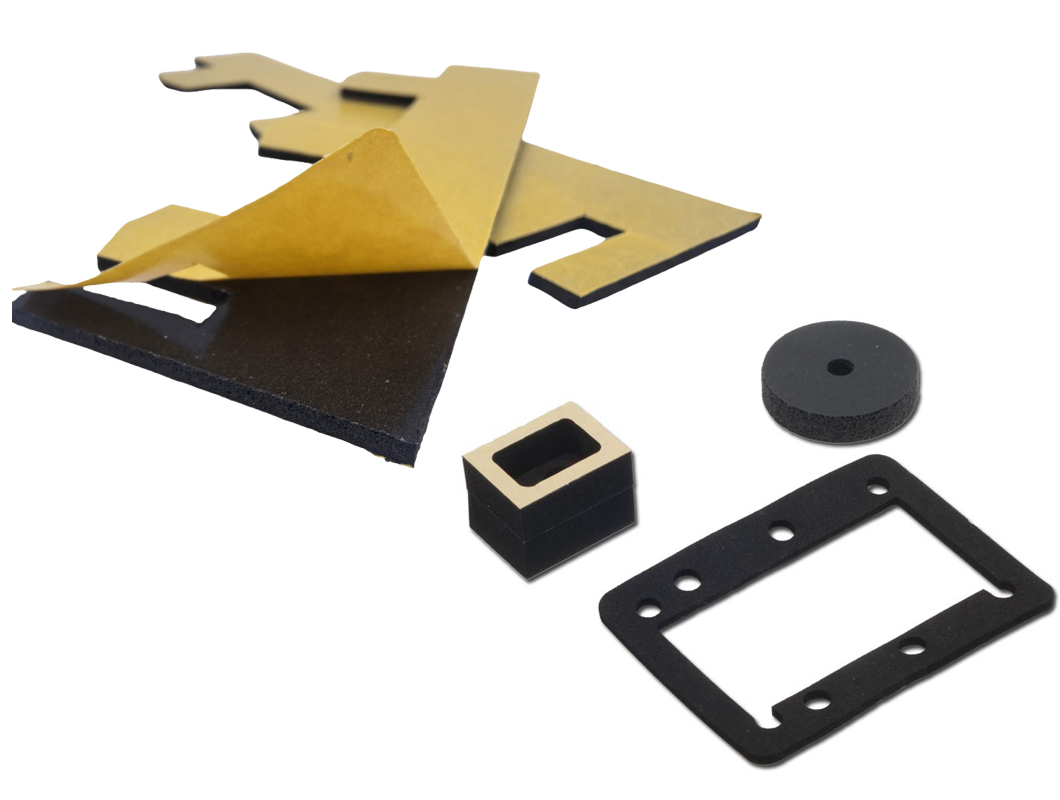

Foam gaskets rank among the most widely utilized components for sealing, cushioning, isolation, and insulation, finding applications across a diverse array of industries—from automotive assemblies and HVAC systems to electronics enclosures and industrial machinery.

In the process of designing or specifying foam gaskets, material selection typically takes center stage. Yet, foam thickness is equally vital. This is because the thickness of a foam gasket exerts a direct influence on its compression performance, deflection characteristics, sealing effectiveness, and overall long-term dependability. So, how exactly does foam thickness shape gasket performance? And what key factors should engineers evaluate when determining the appropriate thickness for their specific application?

Grasping the Basics of Foam Gasketing

Before exploring the specific impacts of thickness, it is essential to first understand the core functional objectives of a foam gasket. At its most fundamental level, a gasket must fulfill the following key roles:

●Establish a dependable seal to keep out dust, moisture, air, or fluids

●Deliver controlled compression when under load

●Adjust to surface irregularities and dimensional inconsistencies

●Resist issues like creep, compression set, and degradation caused by environmental factors

Foam gaskets are frequently made from closed-cell or open-cell materials. Examples include polyethylene (PE), cross-linked polyethylene (XLPE), polyurethane (PU), EPDM, neoprene, and vinyl nitrile (VN)—to name just a few. Each of these materials boasts unique mechanical and chemical properties. However, regardless of the type of foam used, thickness remains a defining factor that shapes the gasket’s overall performance.

Foam Thickness and Its Impact on Compression Performance

Compression vs. Compression Set

The thickness of foam plays a key role in determining how much a gasket can compress before either hitting its "bottoming out" point or losing its long-term elastic properties. From an optimal standpoint, a gasket should function within a compression range of 25% to 50% relative to its initial thickness. If compression exceeds 60%, it can cause the material to deteriorate and result in compression set—a phenomenon where the foam fails to fully bounce back once the applied load is removed.

Thinner foam sheets often reach their critical compression thresholds more quickly and may even bottom out when subjected to moderate loads. In contrast, thicker foam offers a more generous buffer zone, enabling greater deflection before the material’s compression limits are reached.

Load Distribution and Surface Adaptability

Foam thickness also influences how compressive force is distributed and how effectively the gasket can adapt to irregularities on mating surfaces. When sealing against rough, uneven, or non-flat surfaces, thicker gaskets are better equipped to bridge gaps and ensure consistent pressure across the entire contact area.

●A 1/16-inch gasket typically delivers adequate sealing performance between two machined metal surfaces, where the contact plane remains uniform.

●A 1/4-inch gasket, however, may be necessary for use with cast or textured housings, where surface flatness varies more significantly.

Deflection, Resilience, and Energy Absorption Characteristics

Stress-Strain Relationships and Compression Modulus

Foam gaskets are classified as viscoelastic materials, meaning their response to applied stress follows a nonlinear pattern. Thicker foam gaskets typically demonstrate the following traits:

●Reduced initial compression stiffness (this property is also dependent on the foam’s density and inherent modulus)

●Enhanced overall energy absorption capacity

●Larger displacement range before the onset of permanent deformation

The compression modulus—calculated as the ratio of stress to strain—also varies with foam thickness. In general, thicker foams demand less stress to achieve a specific level of strain. This characteristic makes them well-suited for low-load applications, where only a limited amount of closure force is available.

On the other hand, thinner foam gaskets are more appropriate for high-load operating environments or scenarios that require strict adherence to tight dimensional tolerances.

How Thickness Affects Sealing Integrity

Compression Force Deflection (CFD)

CFD is a standard measurement that indicates the amount of force required to compress foam to a specific percentage, usually 25%. As gasket thickness increases, CFD tends to decrease—meaning the foam requires less force to compress. This can be beneficial in lightweight assemblies or plastic housings where fasteners cannot apply high torque.

That said, if the foam is too easily compressed, sealing pressure at the interface may drop, particularly when exposed to vibration or temperature changes. For reliable long-term performance, thickness must be balanced with the right density and firmness.

Gasket Creep and Cold Flow

Thicker foam gaskets are more prone to creep, or gradual deformation under constant load, especially in higher-temperature environments. To reduce this risk, engineers should choose materials with low compression set values. This is especially important in demanding applications such as:

●Under-hood automotive components

●HVAC access panels

●Outdoor electrical enclosures

TOPSUN Foam provides materials designed to meet strict performance standards—including UL 50 / UL 50E, UL 94, FMVSS 302, and ASTM D1056—helping ensure durable sealing across a wide range of foam thicknesses.

When to Choose Thicker vs. Thinner Foam Gaskets

Choose Thicker Foam (1/4″ to 1″+) when:

●Mating surfaces are uneven, warped, or flexible

●Large gaps or tolerance stack-ups must be filled

●Vibration isolation or impact absorption is also required

●The gasket must account for thermal expansion or movement

●Only low compression forces are available (e.g., plastic-to-plastic assemblies)

Choose Thinner Foam (1/32″ to 1/8″) when:

●Mating surfaces are flat, smooth, and precise

●Higher sealing pressure and torque retention are needed

●Space is limited within the design envelope

●Thermal or electrical conductivity must remain consistent

●High compression forces are available (e.g., metal-to-metal enclosures)

Key Factors to Consider

Foam thickness is only one part of gasket design. Selection should also account for:

●Available compression force during assembly

●Tolerance stack-up across components

●Variations in seal gap

●Environmental exposure (temperature, humidity, UV, chemicals)

●Long-term compression set and rebound performance

Foam behavior is not linear—doubling the thickness does not mean doubling compression capability. For the best results, thickness, density, and formulation should be balanced with the help of a materials expert.

Thickness Is a Performance Factor, Not Just a Number

Foam thickness is critical to the reliability of a gasket, particularly in applications requiring long-term sealing, vibration control, or energy absorption. A gasket that's too thin can compromise the seal, while one that's too thick may compress unevenly or break down over time.

At TOPSUN Foam, we help engineers, OEMs, and designers fine-tune gasket designs around actual forces, environments, and usage conditions. From high-volume precision die-cuts to custom prototypes in unique thicknesses, we provide foam solutions engineered for lasting performance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu