Packaging engineers face a critical challenge: protecting products from shock, vibration, and impact while ensuring they remain stable and secure. Excess cushioning can cause items to shift or deform, while excessive rigidity may transfer damaging forces directly to the product.

The solution lies in understanding how various foam materials perform and finding the right balance between cushioning and support. This requires knowledge of foam mechanics, comparison of common foam types, and selecting the most suitable material for the specific product being shipped.

Cushioning vs. Support: Understanding the Difference

In foam engineering, cushioning is the material's ability to absorb energy and limit the transfer of shock or vibration. It is generally characterized by:

●Low to medium density

●Softer compression response

●Greater deflection under load

Support, on the other hand, is a material's resistance to deformation. It reflects how well the foam maintains its shape, prevents movement, and resists collapse under weight.

Although cushioning and support may seem at odds, they are not mutually exclusive. The best foam solutions strike a balance—providing enough give to absorb impact while maintaining the structure needed to keep products secure.

Foam Types: Cushioning vs. Support Properties

Polyurethane (PU) Foam

Polyurethane is one of the most widely used foams in protective packaging. As an open-cell material, it provides strong cushioning with light to moderate support. It compresses easily, recovers well, and is commonly used for:

●Delicate electronics

●Fragile instruments

●Lightweight retail goods

Pros:

●Excellent energy absorption

●Lightweight and flexible

●Available in many firmness options

Cons:

●Limited structural support

●Not suitable for heavy or high-load products

Expanded Polyethylene (EPE) Foam

EPE is a semi-rigid, closed-cell foam that balances impact absorption with structural strength. It is frequently used in:

●Appliances, electronics, and medical devices

●Commercial, retail, and contractor case inserts

●Industrial parts

●Cold chain packaging

●Returnable systems and dunnage

Pros:

●Strong impact resistance

●Uniform compressive strength and creep resistance

●Class A surface finish

●Broad density range for diverse applications

●Excellent strength-to-weight ratio

●Recyclable and reusable

●Low water absorption

Cons:

●Less compressible than PU

Polyethylene (PE) Foam

PE foam is an extruded, closed-cell material suitable for many general packaging needs.

Pros:

●Good impact resistance

●Available in multiple densities for different applications

●Recyclable with cost-effective recycled options

●Fire-retardant and anti-static grades available

Cons:

●Less durable than EPE or XLPE

Cross-Linked Polyethylene (XLPE) Foam

XLPE is a high-performance, closed-cell foam offering smooth surface finish, excellent durability, and superior structural integrity. Firmer than PU or EPE, it still delivers effective shock absorption with a higher compression modulus.

Applications:

●Medical device packaging

●Military transport cases

●Automotive and aerospace assemblies

Pros:

●Maintains shape and resists deformation

●Strong chemical and water resistance

●Ideal for high-value, high-precision parts

Cons:

●More rigid with less cushioning feel than open-cell foams

●Higher cost compared to PU or EPE

Expanded Polypropylene (EPP) Foam

EPP is a bead foam similar to EPE but with greater resilience and excellent multi-impact performance. It is preferred in applications requiring both cushioning and long-term support, including:

●Reusable shipping containers

●Pallets and crates

●Automotive interior parts

●Robotics and drone packaging

Pros:

●High strength-to-weight ratio

●Excellent for dynamic and returnable systems

●Strong compression recovery

Cons:

●More challenging to fabricate at higher densities

How to Balance Cushioning and Support in Protective Packaging

The best foam solution isn't about simply choosing the softest or firmest option—it's about matching the right density, thickness, and structure to your product's unique protection needs. Here's how to approach it:

1. Understand Product Fragility and Weight

●Lightweight & Fragile (cameras, sensors, glassware):

Use low-density PU or EPE for strong shock absorption with gentle compression.

●Heavy & Durable (metal parts, tools, batteries):

Choose firmer, high-density foams like XLPE or EPP to maintain support and prevent shifting.

●Medium-Weight & Semi-Fragile (electronics, enclosures):

Combine cushioning and rigid layers—for example, a PU insert within a PE shell.

2. Evaluate the Shipping Environment

●Long-distance transit, rough handling, or frequent stacking may require multi-layer packaging.

●Outer layers provide structural support, while inner layers deliver cushioning.

●Custom lamination makes it possible to combine multiple foam types for optimal performance.

3. Factor in Compression and Recovery

●PU foam compresses easily but may take a set under constant load.

●EPE, EPP, and XLPE offer better shape retention under static and dynamic stresses, making them well-suited for long-term or returnable packaging.

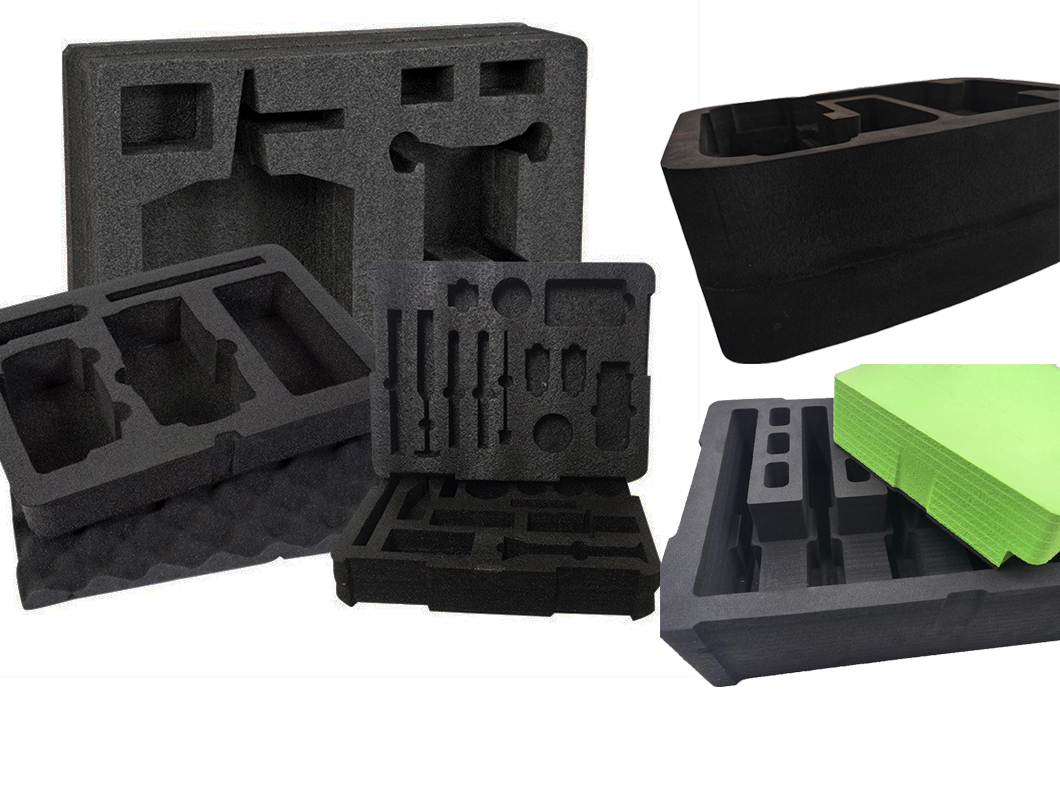

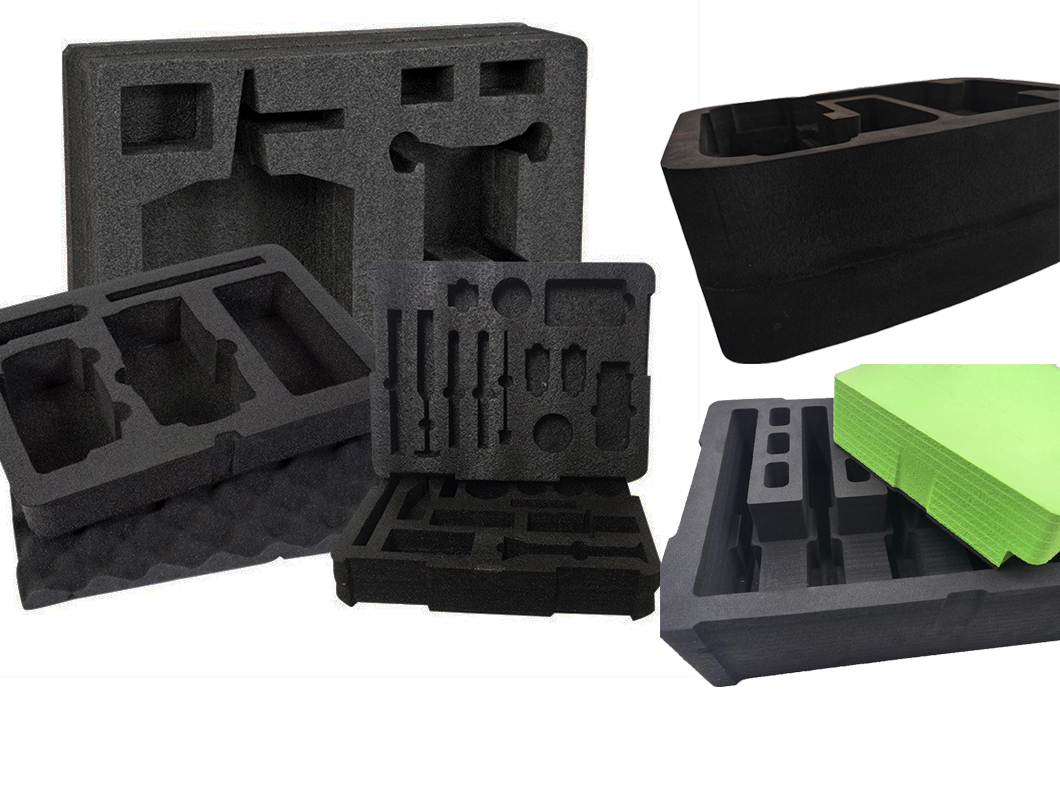

4. Ensure Custom Fit and Fabrication

Foam protection depends on precision fit. Custom-cut foam ensures:

●Even pressure distribution

●No shifting during transport

●Minimal void space for maximum cushioning efficiency

Advanced fabrication methods—CNC routing, waterjet cutting, and die cutting—allow exact-fit solutions tailored to your product's shape, weight, and protection requirements.

Find the Right Foam with TOPSUN

Cushioning and support aren't opposites—they work together to create effective protection. The key is selecting the right material, thickness, and cut to achieve the perfect balance.

At TOPSUN Foam, we partner with OEMS, Supplier, and packaging engineers to deliver that balance. With a broad range of engineered foam materials, precision fabrication, and expert design support, we create inserts, cavities, and pads tailored to your product's exact requirements.

Looking for the ideal mix of softness and strength? Contact the TOPSUN Foam team today to explore custom packaging solutions.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu