♦Full rolls, strip cut lengths, gaskets & adhesive tapes.

EPDM (Ethylene Propylene Diene Monomer) foam

EPDM (Ethylene Propylene Diene Monomer) foam which is a closed cell mid-density foam rubber material which are versatile in a wide range of industrial and commercial applications.

It outperforms in many aspects than other foam rubber material including aging properties, durability, compressibility, thermal durability and excellent slip resistance.

EPDM foam is also excellent at shock & sound insulation, moisture & sunlight resistance and wide operative temperature.

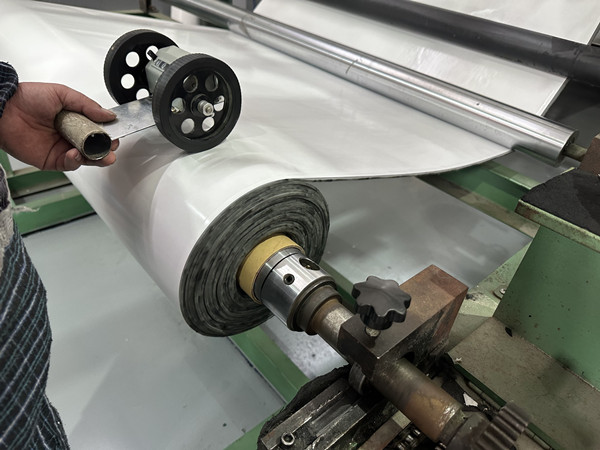

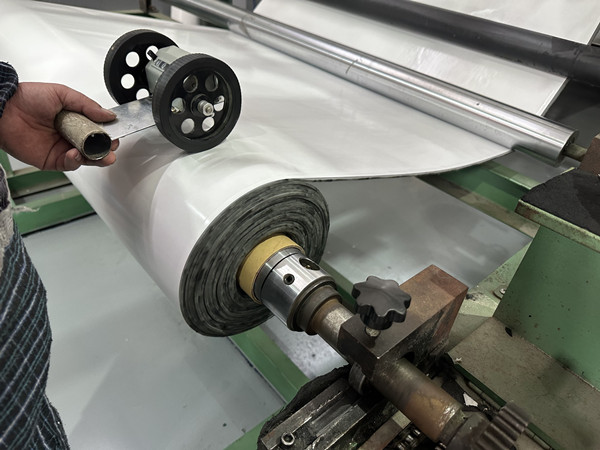

Our EPDM sponge is available in various thickness from 0.5 mm to 40 mm. It can be easily processed by our state of machinery into sheets, rolls, strips, tape with or without adhesive and blocks. With impressive resistance to light and ozone and functions well in a wide temperature range, our EPDM foam is perfect for outdoor uses.

It is used in various applications including construction, HVAC, transportation, automotive and general appliances and machinery in form of EPDM foam seals, gaskets, strips, tapes or sheets with or without aggressive self-adhesive backings.

Our EPDM sponge rubber is a high-quality, closed cell material that is commonly used to create an air and watertight seal. EPDM sponge is great for use in outdoor sealing applications due to the superior UV and Ozone resistance the material offers. Aside from offering excellent weathering resistance, EPDM also features good flexibility, tensile strength and recovery properties. The closed cell structure enables the material to handle high-pressure sealing applications at a better rate. This serves to increase the life expectancy of the material in physically demanding applications.

A key feature of our closed cell EPDM sponge rubber is the materials air and watertight structure. This provides excellent thermal sealing as well as preventing the build-up of bacteria and mould. The closed cell structure also enables our material to create a seal using minimal rates of compression. However, the sealing properties of the material can vary depending on the density. Don’t hesitate to get in contact with us if you are unsure which density best suits your application.

2.Who we are ?

Topsun, the Professional supplier for the Foams, we can provide a variety of foam products, such as EVA foam, PE foam, neoprene foam, EPDM foam and NBR foam.At the same time, we have advanced processing capabilities to convert foam into the products you need.

4.What kinds of foam materials we can supply ?

We can supply :EVA foam, PE foam, XPE foam, IXPE foam, CR foam, EPDM foam, Neoprene foam, SBR foam, NBR foam, Micro-cell soft PVC foam. All of them we can supply in sheet and roll.

5.What's the processing capacity we have ?

1. Cutting - cutting the size as per client’s request

2. Slicing - Slicing the thickness as per client’s request

3. Lamination - hot melt film lamination, flame lamination, and pressure-sensitive adhesive lamination

4. Laser Vibrator - New type cutting machine, can cut the foam drawing without open molds

5. Die cutting - Open molds as per your design then at first, use die cutting machine to produce, it’s quicker than laser vibrator.

6. Compression Molding - Compression molding is a process we utilizes for the manufacturing of three-dimensional molded foam and foam composite parts. It is an ideal process for making parts that have intricate features, require very defined part geometry, have varying wall thicknesses or need to be held to critical dimensional tolerances.

7. Engraving machine - Usually to make tool box insert and packing insert as per client’s requests.

8. Silk-screen printing - Print logos and patterns on the surface of foam products

9. Adhesive backing - Gluing on the surface of the foam with liners. Usually produce foam tapes and other products need to stick on.

6.Where is our facility located ?

Our factory is located in Changzhou city, Jiangsu Province. One hour driving to Shanghai Port.

7.How to get samples ?

Send enquiry to july@topsunfoam.com, with your details of the foams need, we will check reply in 24 hours.We are committed to continuously providing excellent products and services to customers worldwide

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu

EPDM (Ethylene Propylene Diene Monomer) foam

EPDM (Ethylene Propylene Diene Monomer) foam