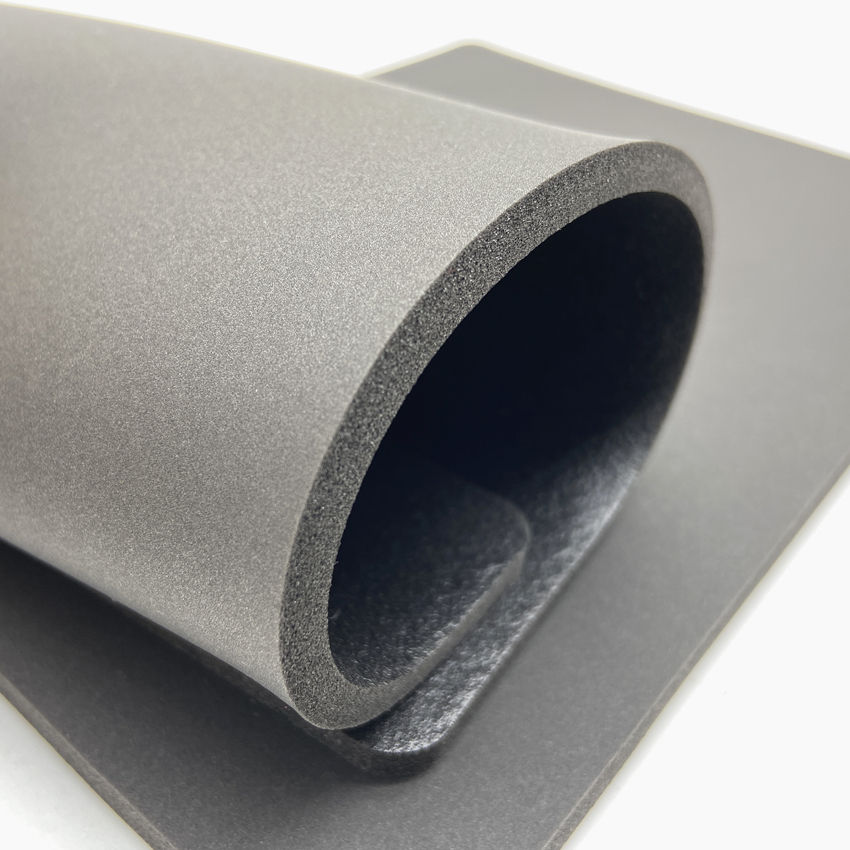

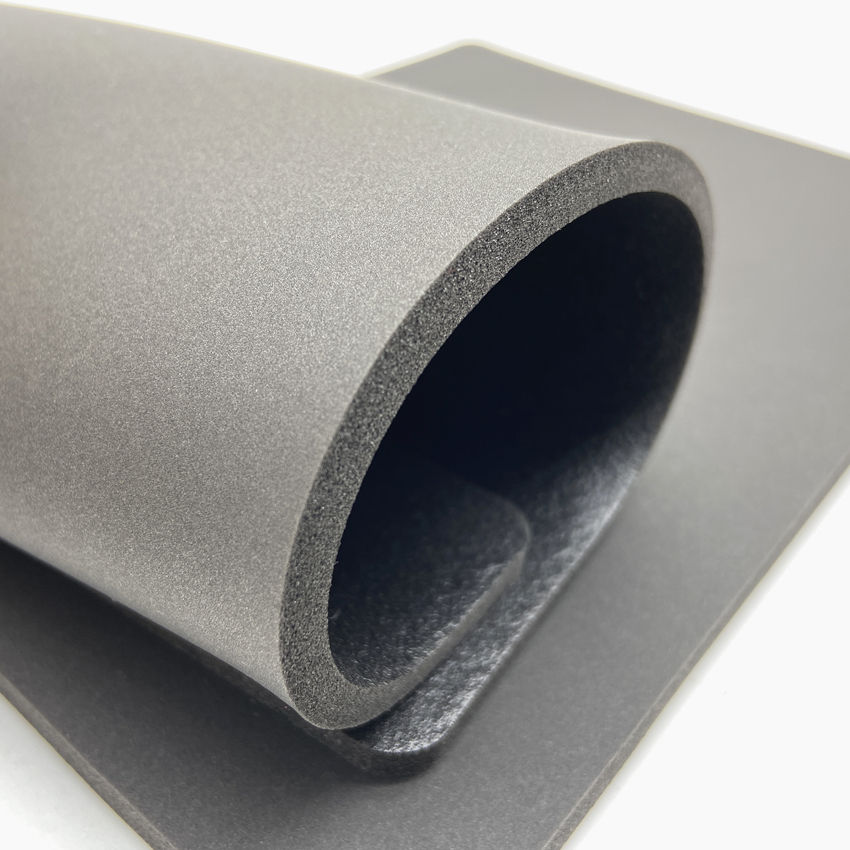

PVC Sponge Foam Closed Cell Rubber Foam Features:

•Closed cell structure, with excellent dust-proof and waterproof performance

•Strong sealing ability

•Weather resistance and low temperature resistance

•Sound insulation and vibration damping

•Conforms to curves and irregular shapes

Specification of PVC Sponge Foam:

| Property | Test Method | Value or Rating |

| Density | ASTM D1667 | 250±30kg/m3 |

| Hardness(Shore 00) | ASTM D2240 | 50±7 ° |

| Tensile Strength | ASTM D412 | ≥450kPa |

| Elongation at Break | ASTM D412 | ≥110% |

| Force to Compress by 25% | ASTM D1667 | ≥30kPa |

| 30% Compression Set | ASTM D1667 | ≤5% |

| Flammability | UL94 | Available

In Customized |

| FMVSS 302 | Pass |

| ROHS | 2011/65/EU&(EU)2017/2102 | Pass |

| PFOA / PFOS | CEN/TS 15968(2010) | Pass |

PVC Sponge Foam FAQ

1.What is PVC Sponge Foam ?

Polyvinyl Chloride (PVC) Foam is a closed-cell PVC foam designed to provide an economical solution for sealing light, air, moisture, and more. By adjusting the foam's density (80kg/m³~500kg/m³), softness/hardness (Shore 00 5°~99°), resilience, and other properties, it can deliver performance tailored to various application scenarios. It is highly suitable for a wide range of uses, such as vehicle body vibration damping, door and window sealing, water tank sealing, HVAC sealing, cushioning for electronic products, and more.

2.What is Application of PVC Sponge Foam ?

●Door and window sealing strips

●Truck, cab, and vehicle body seals

●HVAC sealing

●Appliance sealing

●Die-cut gaskets

●Electronic device sealing

●Railway/marine applications

●Outdoor lighting fixtures

3.Who are you?

Topsun, the Professional supplier for the Foams, we can provide a variety of foam products, such as EVA foam, PE foam, neoprene foam, EPDM foam and NBR foam.At the same time, we have advanced processing capabilities to convert foam into the products you need.

4.What kinds of foam materials we can supply ?

We can supply :EVA foam, PE foam, XPE foam, IXPE foam, CR foam, EPDM foam, Neoprene foam, SBR foam, NBR foam, Micro-cell soft PVC foam. All of them we can supply in sheet and roll.

5.What's the processing capacity we have ?

1. Cutting - cutting the size as per client’s request

2. Slicing - Slicing the thickness as per client’s request

3. Lamination - hot melt film lamination, flame lamination, and pressure-sensitive adhesive lamination

4. Laser Vibrator - New type cutting machine, can cut the foam drawing without open molds

5. Die cutting - Open molds as per your design then at first, use die cutting machine to produce, it’s quicker than laser vibrator.

6. Compression Molding - Compression molding is a process we utilizes for the manufacturing of three-dimensional molded foam and foam composite parts. It is an ideal process for making parts that have intricate features, require very defined part geometry, have varying wall thicknesses or need to be held to critical dimensional tolerances.

7. Engraving machine - Usually to make tool box insert and packing insert as per client’s requests.

8. Silk-screen printing - Print logos and patterns on the surface of foam products

9. Adhesive backing - Gluing on the surface of the foam with liners. Usually produce foam tapes and other products need to stick on.

6.Where is our facility located ?

Our factory is located in Changzhou city, Jiangsu Province. One hour driving to Shanghai Port.

7.How to get samples ?

Send enquiry to july@topsunfoam.com, with your details of the foams need, we will check reply in 24 hours.We are committed to continuously providing excellent products and services to customers worldwide.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu