Here we are going to elaborate open cell foam materials from some aspects in detail.

Polyurethane foam is one of the most frequently-used open cell foams. They are widely used in insulation, sound and shock absorption application across a range of industries and materials, including furniture upholster, seat cushion, medical packaging, electronics, power equipment and so much more. Open cell Polyurethane foams are superior to other forms of insulation for their dexterity and resistance to oxygen.

You might be puzzled to hear that something solid is also made of Polyurethane foam. The fact is actually that Polyurethane foam comes in two forms- open cell or closed cell structure, both of which differ in densities and respective applications. However, in this post, we focus on open cell Polyurethane foam materials.

Besides Polyurethane foam can also be provided in open cell structure. PVC/ Nitrile foam and EPDM foam rubber are available for open cell foams as well.

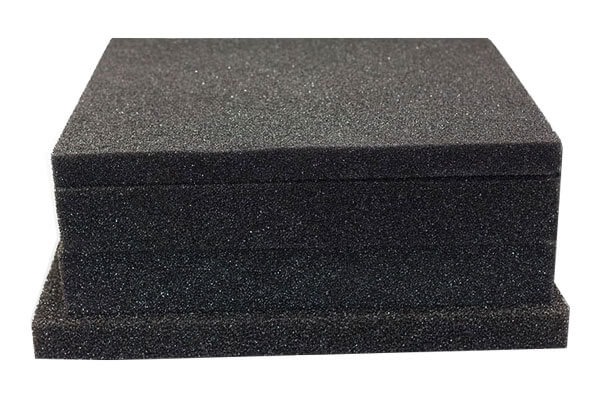

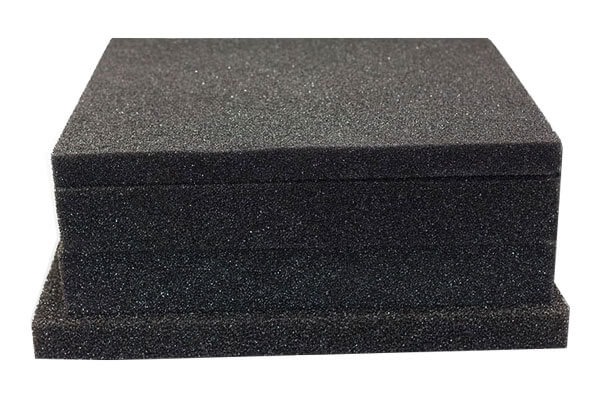

Open cell foams take Polyurethane foam sheets as an example where the cells within the material have been broken, allowing air to occupy the spaces within. Usually open cell foams are lightweight and less dense compared with closed cell foams, and they have a soft, cushioning and sponge-like appearance.

During an open cell foams expansion and curing, the gas bubbles used in its production are released into the atmosphere as against being locked in place as with closed cell foams. These holes within open cell foams enable them to interlock and interconnect. Due to this porous nature, open cell foams can not resist liquid water or water vapor.

2.FEATURES AND ADVANTAGES OF OPEN CELL FOAM

Some of the features and benefits of the open cell foam include:

•It doesn’t contain any volatile organic compounds or ozone depleting gases

•It is ideal for minimizing noise transmission

•It produces little or no residual particles, and traps most foreign particles in its pore spaces, making it ideal for reducing dust and allergens

•It is mold growth resistant

•It is good at sound proofing

•It has a good insulation value of approximately R-4.21 per inch

•It accounts for about 40-50% of heat gain/loss in apartments

•It is durable and will not break, shrink or diminish over time

•It has a high expansion capacity, capable of expanding up to 100 times

•It has a low density of between 0.4 and 1.2 lbs./ft3

3.What is Application of EVA foam

PE foam is a very versatile product. It is suitable for a wide range of different uses and applications, such as Marine flooring materials, orthopedic EVA blocks. It is an effective substitute for many materials. Such as felt, neoprene, natural rubber, polyurethane foam, PVC foam, wood composites, mineral wool and glass fiber.

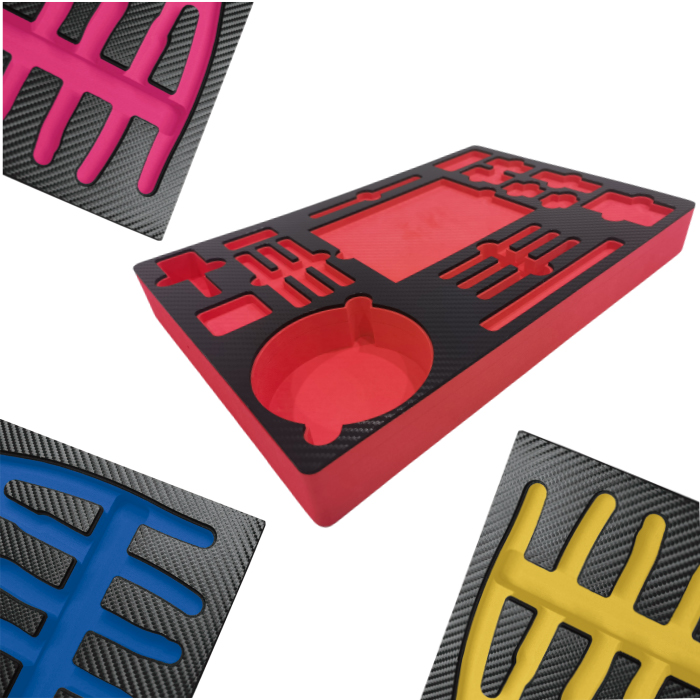

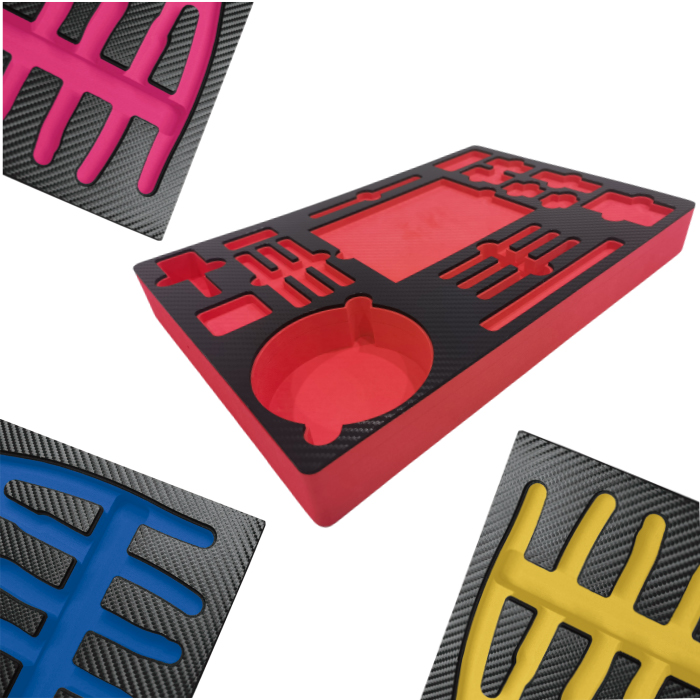

EVA FOAM TOOL BOX INSERT

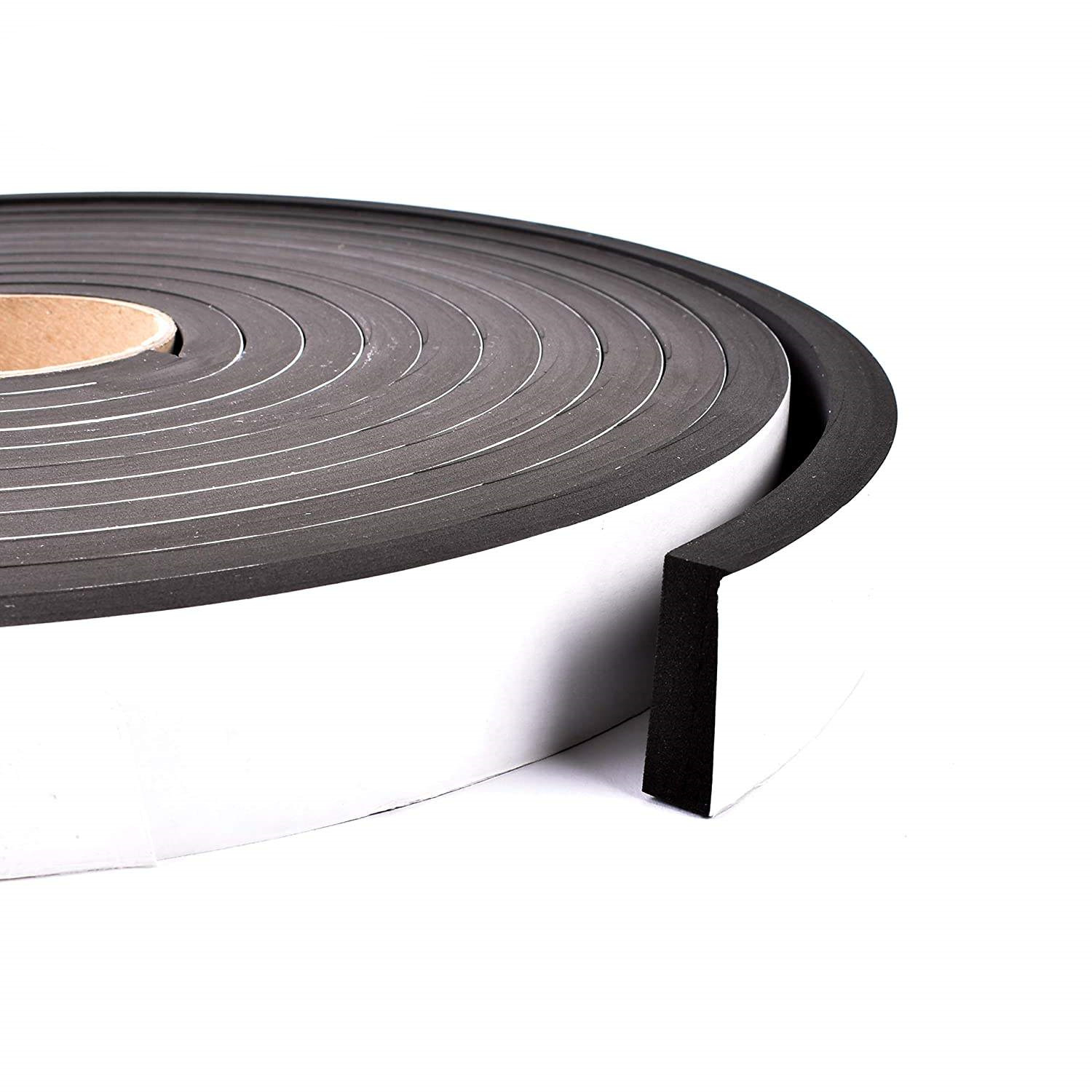

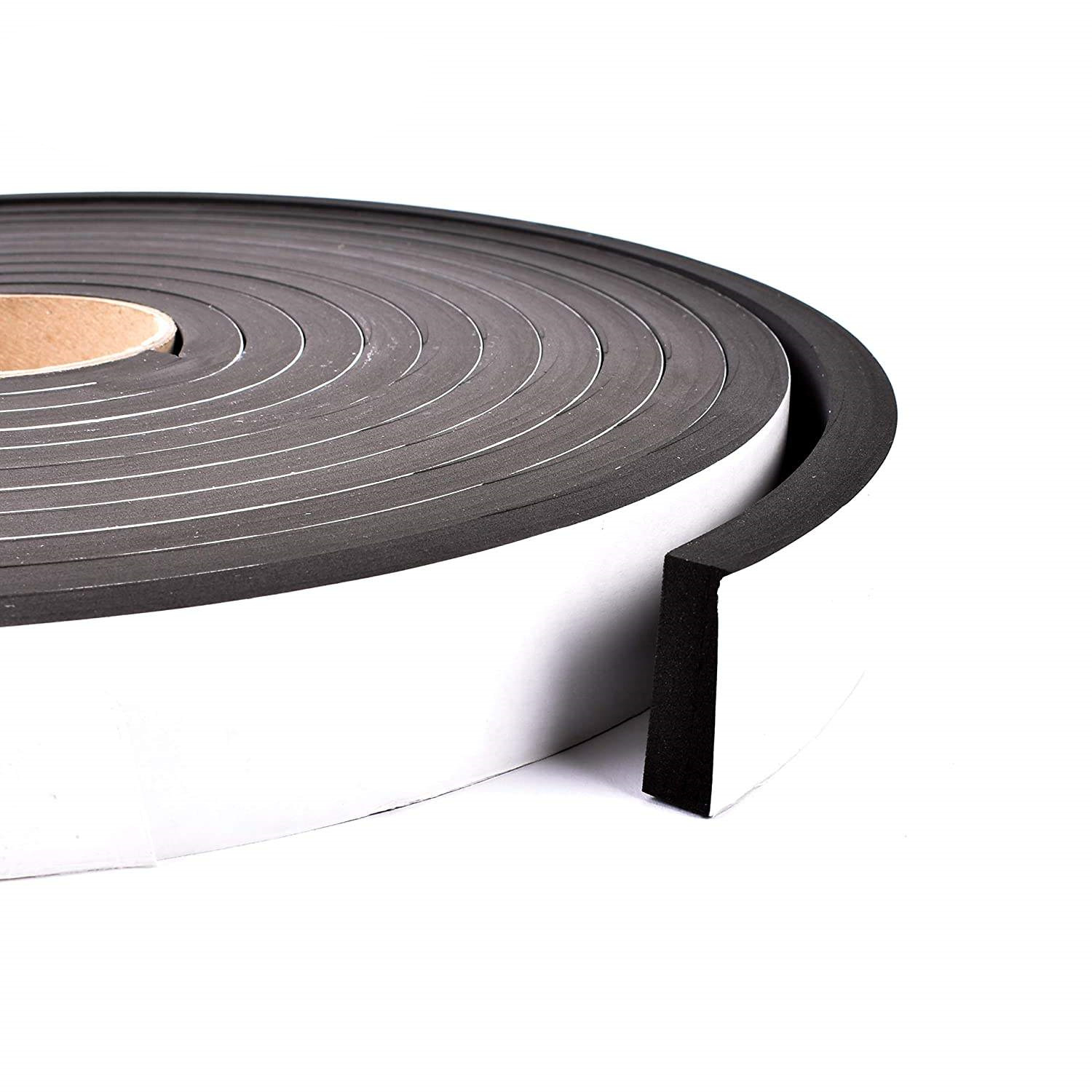

EVA FOAM TAPE

EVA FOAM TAPE

EVA FOAM ROLLS

4.Who are you?

Topsun, the Professional supplier for the Foams, we can provide a variety of foam products, such as EVA foam, PE foam, neoprene foam, EPDM foam and NBR foam.At the same time, we have advanced processing capabilities to convert foam into the products you need.

5.What kinds of foam materials we can supply ?

We can supply :EVA foam, PE foam, XPE foam, IXPE foam, CR foam, EPDM foam, Neoprene foam, SBR foam, NBR foam, Micro-cell soft PVC foam. All of them we can supply in sheet and roll.

6.What's the processing capacity we have ?

1. Cutting - cutting the size as per client’s request

2. Slicing - Slicing the thickness as per client’s request

3. Lamination - hot melt film lamination, flame lamination, and pressure-sensitive adhesive lamination

4. Laser Vibrator - New type cutting machine, can cut the foam drawing without open molds

5. Die cutting - Open molds as per your design then at first, use die cutting machine to produce, it’s quicker than laser vibrator.

6. Compression Molding - Compression molding is a process we utilizes for the manufacturing of three-dimensional molded foam and foam composite parts. It is an ideal process for making parts that have intricate features, require very defined part geometry, have varying wall thicknesses or need to be held to critical dimensional tolerances.

7. Engraving machine - Usually to make tool box insert and packing insert as per client’s requests.

8. Silk-screen printing - Print logos and patterns on the surface of foam products

9. Adhesive backing - Gluing on the surface of the foam with liners. Usually produce foam tapes and other products need to stick on.

7.Where is our facility located ?

Our factory is located in Changzhou city, Jiangsu Province. One hour driving to Shanghai Port.

8.How to get samples ?

Send enquiry to july@topsunfoam.com, with your details of the foams need, we will check reply in 24 hours.We are committed to continuously providing excellent products and services to customers worldwide.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu