EPP foam boxes Description:

An EPP (Expanded Polypropylene) foam box is a strong and versatile container made from a lightweight thermoplastic polymer. Known for its excellent cushioning, thermal insulation, and impact resistance, it is widely used in packaging, transportation, and storage. EPP foam boxes protect items from mechanical damage, help maintain stable temperatures for sensitive goods, and offer long-lasting durability even with repeated use.

EPP foam boxes Features:

●Impact Resistance: Effectively absorbs shocks and impacts, keeping items safe during handling and transport—ideal for fragile products like electronics, medical devices, and glassware.

●Thermal Insulation: Maintains stable temperatures, making it suitable for perishable goods, pharmaceuticals, and other temperature-sensitive items.

●Lightweight Strength: Combines durability with low weight, reducing shipping costs and simplifying handling.

●Moisture & Chemical Resistance: Naturally resistant to water, oils, solvents, and most chemicals, protecting contents from contamination or damage.

●Durability & Reusability: Built for long-term use and multiple reuses, helping reduce reliance on single-use packaging.

●Customizable Design: Can be molded into different shapes, sizes, and densities to match specific packaging requirements.

●Eco-Friendly: Fully recyclable, supporting sustainable and environmentally responsible practices.

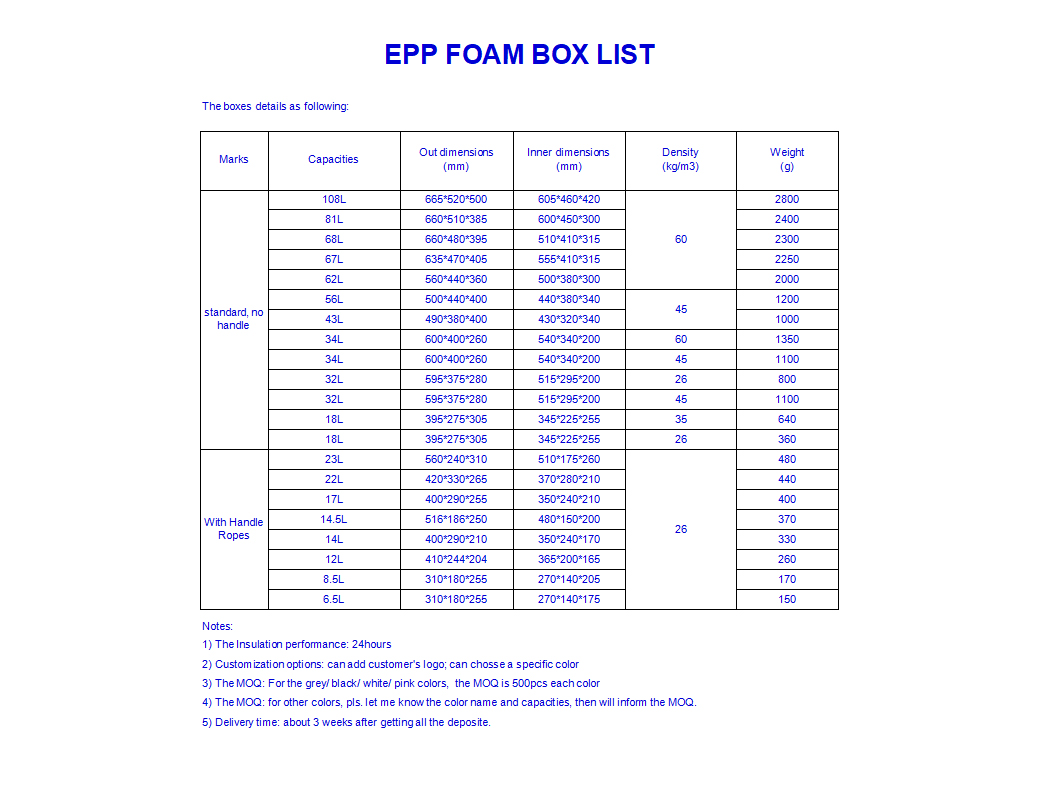

Specification of EPP foam boxes:

EPP foam boxes FAQ:

1.What is EPP foam boxes?

EPP foam:

Due to the mechanical properties of EPP, EPP is particularly suitable for components subject to impact stress. The low weight, high energy absorption and good deformation performance of EPP, even after repeated impact loading, represent outstanding qualities for components in automotive assembly.

EPP also has negligible water absorption, can function reliably over a wide range of temperatures, and is thus predestined for internal and external applications in automotive assembly. Additionally, low manufacturing costs

and - compared to other foam materials - minimal tooling costs offer distinct advantages as well.

Examples of safety-relevant applications include: foam inserts allowing for protection against lateral impact,

energy absorbing bumper cores as well as knee pads and steering column casings. The resilient response of side impact protection pads made of EPP is markedly delayed and thus meets essential industry safety requirements. Moreover, shock absorbing systems, door, head rest, panels and other components assembled using parts made

of EPP comply with the existing legal regulations.

In a high density grade, the material can also be used as a structural element. Its high strength and good compatibility with other materials allows it to produce components distinguished by outstanding mechanical properties.

Easy to produce in different geometric shapes, the material is particularly suitable for fabricating filler elements and tool caddies, with the low weight per unit volume providing a remarkable weight reduction.

More and more, new automotive designs value materials that offer weight saving and recyclable, No other foam material meets these requirements to the same extent as EPP. Since component weights can be efficiently reduced, significant cost and energy savings are feasible. As such, EPP contributes greatly to the preservation of the environment and the conservation of resources, while also meeting the escalating safety standards in the industry.

2.Applications of EPP Foam Boxes:

Protective Packaging: Ideal for transporting electronics, automotive parts, and other delicate or high-value items that demand reliable protection.

Cold Chain Logistics: Perfect for food, beverages, pharmaceuticals, and biological samples that must remain within strict temperature ranges.

Reusable Transport Containers: Highly durable, making them well-suited for logistics and supply chain operations involving repeated use.

Specialty Packaging: Used in diverse applications such as protective cases for sports equipment, insulated containers for food delivery, and innovative consumer packaging solutions.

3.Who are you?

Topsun, the Professional supplier for the Foams, we can provide a variety of foam products, such as EVA foam, PE foam, neoprene foam, EPDM foam and NBR foam.At the same time, we have advanced processing capabilities to convert foam into the products you need.

4.What kinds of foam materials we can supply ?

We can supply :EVA foam, PE foam, XPE foam, IXPE foam, CR foam, EPDM foam, Neoprene foam, SBR foam, NBR foam, Micro-cell soft PVC foam. All of them we can supply in sheet and roll.

5.What's the processing capacity we have ?

1. Cutting - cutting the size as per client’s request

2. Slicing - Slicing the thickness as per client’s request

3. Lamination - hot melt film lamination, flame lamination, and pressure-sensitive adhesive lamination

4. Laser Vibrator - New type cutting machine, can cut the foam drawing without open molds

5. Die cutting - Open molds as per your design then at first, use die cutting machine to produce, it’s quicker than laser vibrator.

6. Compression Molding - Compression molding is a process we utilizes for the manufacturing of three-dimensional molded foam and foam composite parts. It is an ideal process for making parts that have intricate features, require very defined part geometry, have varying wall thicknesses or need to be held to critical dimensional tolerances.

7. Engraving machine - Usually to make tool box insert and packing insert as per client’s requests.

8. Silk-screen printing - Print logos and patterns on the surface of foam products

9. Adhesive backing - Gluing on the surface of the foam with liners. Usually produce foam tapes and other products need to stick on.

6.Where is our facility located ?

Our factory is located in Changzhou city, Jiangsu Province. One hour driving to Shanghai Port.

7.How to get samples ?

Send enquiry to july@topsunfoam.com, with your details of the foams need, we will check reply in 24 hours.We are committed to continuously providing excellent products and services to customers worldwide.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Afrikaans

नेपाली

Oʻzbekcha

Azərbaycan dili

Български

guarani

Hausa

Kurdî

Kurdî

Lietuvių

Wikang Tagalog

isiZulu